UL 5085-2-2021 pdf download.Low Voltage Transformers – Part 2:

General Purpose Transformers.

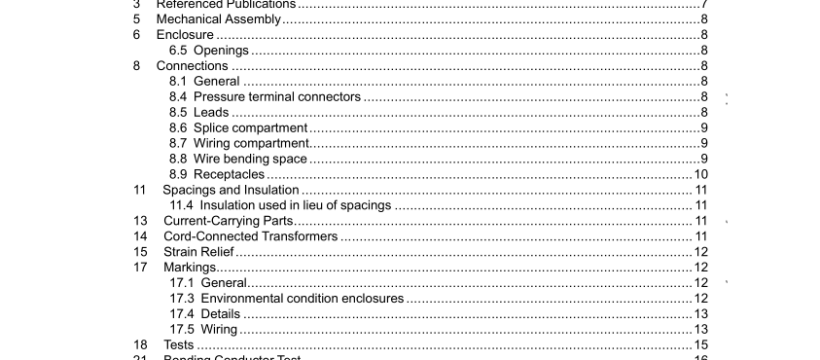

5 Mechanical Assembly 5.4 A transformer weighing more than 45 kg (100 lbs) shall be provided with a means for lifting by a forklift, cable, sling, or similar method. The lifting means may be provided on the transformer core or frame if the transformer has a removable top cover. The lifting means shall be subjected to the Lifting or Mounting Means Test in Clause 37. Note: The lifting means test does not apply to a transformer that is intended to be lifted from underneath by a forklift or other method. 6 Enclosure 6.5 Openings 6.5.2 Openings shall prevent passage of a straight rod 12.7 mm (0.5 inch) in diameter. When the distance between live parts and the enclosure and between the plane of the ventilation opening and live parts is 102 mm (4 inches) or more, openings shall be constructed so that they will prevent passage of a rod 19 mm (0.75 inch) in diameter. When the distance between the plane of the opening and uninsulated live parts is less than 102 mm (4 inches), the rod shall have a cross-section of 13.4 mm (0.53 inch). 8 Connections 8.1 General 8.1.4 A transformer shall have provision for the connection of supply and load conductors, either in the form of busbars, leads, pressure terminal connectors, or terminal pads for pressure terminal connectors. Note: Studs or wire binding screws may be used for field connections when the full load current of the terminal is 24 A or less and the transformer is marked in accordance with Clause 17.5.5. The studs or wire binding screws may be used for the field connection of 5.3 mm 2 (10 AWG) or smaller conductors. 8.4 Pressure terminal connectors 8.4.5 More than one wire connector may be provided for a single connection point to allow for connection of the various size conductors which require accommodation. In such case, each connector shall be marked in accordance with Clause 17.5.7.

8.5.10 When a transformer is not intended for outlet box mounting and is not provided with a terminal or winding compartment, the leads shall enter the enclosure either through a nipple or other means for the attachment of rigid metal conduit. Alternatively, the leads shall enter through separate holes that provide a spacing of not less than 6.4 mm (0.25 inch) between the conductors and not less than 12.7 mm (0.5 inch) between the conductors and the plane of the transformer support. 8.5.11 Transformers, and their external leads, intended for installation in other enclosures (e.g., control circuit transformers housed with industrial control equipment) may have: a) Primary and secondary leads in the same opening, when they have insulation suitable for the highest voltage involved and a temperature rating of at least 105 °C (221 °F) and b) Metal grommets or smooth, folded edges. 8.5.12 One of the secondary terminals or leads of an autotransformer intended for operation on a circuit of 150 V or less to ground shall be identified for the connection of a grounded circuit conductor. It shall be directly connected to a similarly identified primary terminal or lead. The identification shall be as specified in Clause 17.5.1. 8.6 Splice compartment 8.6.1 When a transformer is provided with leads to which field conductors will be spliced, the leads shall be located in a space providing a usable volume in compliance with Table 1. 8.7 Wiring compartment 8.7.1 A wiring-compartment intended for field connections shall be free of sharp edges, burrs, fins, or moveable parts that can damage conductor insulation.

8.8.3 For wires that do not enter an enclosure through the portion of the wall opposite the field wiring terminals, wire bending space shall not be less than that shown in Table 5 for the maximum size and number of wires intended when: a) They are required to make only one 90 degree bend after the wires enter the enclosure; or b) The wires enter a space having a width not less than that shown in Table 3 for the maximum size and number of wire(s) intended, and this space opens directly into the wire bending space. In both cases the intended wiring method shall be ensured by suitably located knockouts, openings, or by a diagram supplied with the equipment. 8.8.4 The wire bending space at a field wiring terminal shall be measured: a) From the enclosure wall opposite it; b) From the center of the conductor opening on the face of the wire connector; and c) From the line in which the wire leaves the connector (when the connector is at the smallest angle to the perpendicular) to the enclosure wall that it can assume without defeating any integral means provided to prevent turning. A connector shall not be directed at a corner or a recess in an enclosure to obtain the required bending space.UL 5085-2-2021 pdf download.

UL 5085-2-2021 pdf download