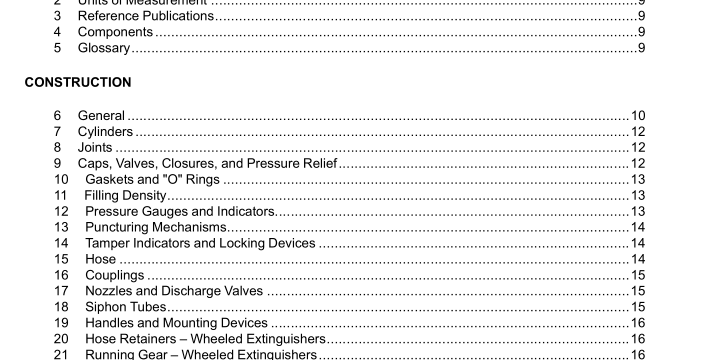

UL 2129-2021 pdf download.Halocarbon Clean Agent Fire Extinguishers.

27 Tamper Indicator and Locking Device Tests 27.1 The tamper indicator shall break when subjected to a force of 65 N (15 lb-f) or less. Exception: When the tamper indicator is broken by the action required to start discharge of the extinguisher, orwhen an internal load is continuously applied to the release mechanism, the force, applied as intended and required to accomplish discharge shall not exceed 130 N (30 lb-f). See 27.4. 27.2 The force required to extract or dislodge a locking device as intended along its axis shall not exceed 130 N (30 lb-f) after the locking device is subjected to the tests specified in 27.3 and 27.4. 27.3 A locking device shall not shear when a force of 220 N (50 lb-f) is exerted upon the operating mechanism for 30 seconds, and the extinguisher then shall be capable of being operated in its intended manner. An extinguisher, with its locking device and tamper indicator attached as intended, is to be secured on the floor in a vertical position and 220 N (50 lb-f) is to be exerted 13 mm (1/2 in) from the end of the operating lever or lever-operated cartridge-puncturing mechanism, or at the center of a punch-button cartridge-puncturing mechanism. 27.4 The extinguisher then is to be secured in a test fixture in a vertical position. The locking device is to be pulled with 130 N (30 lb-f) for 30 seconds at an angle of 45 degrees in an upward direction from the horizontal, and then pulled for 30 seconds at a horizontally rotational angle of 45 degrees. The device shall either: a) Be capable of extraction at the 45 degree angle; or b) Not be damaged or the mechanism jammed to the extent that prevents intended extraction of the locking device directly outward along its axis, when 130 N (30 lb-f) is applied for 30 seconds. 27.5 The 130 N (30 lb-f) force exerted on the locking device both at the 45 degree angle and along the axis of the device is to be achieved by increasing the force from 0 to 130 N (30 lb-f) at a rate of 260 N (60 lb-f) per minute.

28 Handle and Mounting Device Test 28.1 The method of attachment of the handle and hanger loop of a hand-portable extinguisher weighing 1.4 kg (3 lb) or more, and having a cylinder diameter greater than 75 mm (3 in), shall support a static load of five times the fully charged weight of the extinguisher, or 45 kg (100 lb), whichever is greater applied downward through the vertical axis of the extinguisher for 5 minutes. 28.2 A hand-portable extinguisher charged with its rated capacity is to be placed in the bracket or mounting hook provided with the extinguisher after the bracket or mounting hook has been secured to a wood board. The board is to be secured in a vertical position, and the static load then is to be applied to the top of the extinguisher. 28.3 For a bracket mounting device, the force required to open the bracket shall not exceed 65 N (15 lb- f) for finger actuated assemblies and 130 N (30 lb-f) for hand actuated assemblies measured at the end of the bracket opening device. 28.4 A hand-portable extinguisher, charged with its rated capacity, is to be placed in the bracket provided with the extinguisher after the bracket is secured in the vertical position to a wood board. Using a spring scale, or a similar device, a gradually increasing force is to be applied to the tip of the clasp or lever of the bracket strap or band, at a 90 degree angle to the extinguisher, at a rate of 0.45 kg/s (1 lb/s) and until the band releases the bracket. For hand actuated assemblies, when there is an indent or gripping location, the force is to be applied to the center of that actuating area.UL 2129-2021 pdf download.

UL 2129-2021 pdf download