UL 13-2019 pdf download.Power-Limited Circuit Cables.

2 Units of Measurement

2.1 In addition to being stated in the inch/pound units that are customary in the USA. each of the requirements is also stated in units that make the requirement conveniently usable in countries employing the various metric systems (practical SI and customary). Equivalent — although not necessarily exactly identical — results are to be expected from applying a requirement in USA or metric terms. Equipment calibrated in metric units is to be used when a requirement is applied in metric terms.

3 References and Terms

3.1 Wherever the designation “UL 1581” is used in this wire standard, reference is to be made to the designated part(s) of the Reference Standard for Electrical Wires. Cables, and Flexible Cords. UL 1581. Whenever the designation UL 2556” is used in this standard, reference is to be made to the designated parts of the Standard for Wire and Cable Test Methods, UL 2556.

3.2 Any undated reference to a code or standard appearing in the requirements of this standard shall be interpreted as referring to the latest edition of that code or standard.

3.3 Nylon designates a thermoplastic material whose characteristic constituent is a polyamide formed by the condensation of dibasic organic acids and diamines. Nylon used as a covering is unfilled and without reinforcement but may contain stabilizers, flame retardants, pigment, and/or other additives.

3.4 PBT designates a thermoplastic polyester material whose characteristic constituent is polybutylene terephthalate. PBT used as a covering is unfilled and without reinforcement but may contain flame retardants, pigment, andlor other additives.

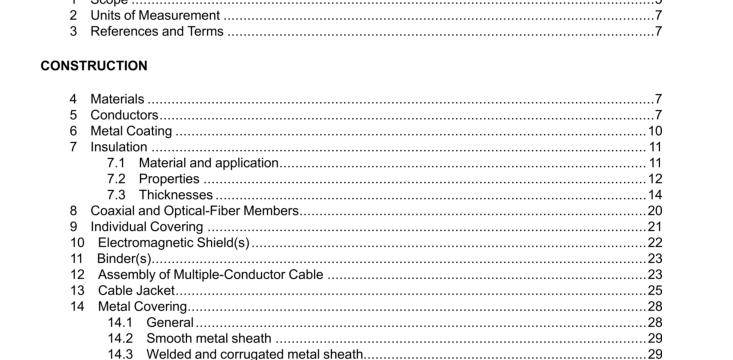

CONSTRUCTION

4 Materials

4.1 Each material used in a cable shall be compatible with all of the other materials used in the cable.

4.2 Power-limited circuit cable shall comply in all respects with the applicable requirements for construction details, test performance, and markings.

5 Conductors

5.1 Conductors shall comply in size (see 52) and material with TabIei. The nominal diameters of solid and stranded conductors which are 30 – 6 AWG conductor size, that are indicated in Table 52 and Table 20.1 in UL 1581 when conductor size is smaller than 30 AWG, are to be used in calculating the dimensions required for various parts of the cable when using Table 13.1. Table 13.2, Table 13.3, Table 14.1, Table 14.2. Table 15.1, and Table 21.1. The length of lay of the wires (strands) of a bunch-stranded conductor shall not exceed 20 times the calculated diameter over the assembled conductor for 19 — 6 AWG conductors and shall not exceed 30 times the calculated diameter over the assembled conductor for 30 — 20 AWG conductors. For a bunch-stranded member of a rope-lay conductor, the length of lay of the individual strands within the bunch shall not be more than 30 times the outside diameter of the member. The length of lay of the member in the outer layer of a rope-lay conductor shall be 8 — 16 times the outside diameter of that layer.

5.5 Any section of conductor that includes a factory joint shall have a tensile strength that is not less than 85 percent of the tensile strength of an adjacent section of the conductor without a joint. 5.6 In place of complying with the d-c resistance requirement in Section 20, at the cable manufacturer’s option, a copper conductor shall instead comply with the fllowing requirement: a) SOLID CONDUCTOR – The diameter of a solid conductor shall not be smaller than the minimum diameter indicated for the size in Table 5.2 (see 5.2) when the diameter of the conductor is determined from measurements as follows: 1) Measurements of the diameter of a solid copper conductor, a copper-clad steel conductor or silver plated steel conductor are to be made by optical means or by means of a machinist’s micrometer caliper having flat surfaces both on the anvil and on the end of the spindle. In either case, the equipment is to be calibrated to read directly to at least 0.001 in or 0.01 mm, with each division of a width that facilitates estimation of each measurement to 0.0001 in or 0.001 mm. The maximum and minimum diameters at a given point on the solid conductor are each to be recorded to the nearest 0.0001 in or 0.001 mm, added together, and divided by 2 without any rounding off of the sum or resulting average. 2) Each minimum diameter indicated in Table 5.2 is an absolute minimum. The unrounded average of the two diameter readings is therefore to be compared directly with the minimum in the table for the purpose of determining whether the solid conductor does or does not comply with the diameter requirement.UL 13-2019 pdf download.

UL 13-2019 pdf download