UL 10C-2021 pdf download.Positive Pressure Fire Tests of Door Assemblies.

10 Supporting Construction 10.1 Wall construction materials shall have the strength to retain the assembly securely in position throughout the Fire Endurance Test, Section 11, and the Hose Stream Test, Section 12. 11 Fire Endurance Test 11.1 Prior to the start of the endurance test the pressure in the furnace chamber is to comply with Clause 7.2. 11.2 Within 5 minutes of elapsed time into the fire exposure, the neutral plane of the furnace is to be established at a maximum of 40 in (1016 mm) up from the bottom of the test assembly. 11.3 The pressure that is maintained over the top one-third of the door assembly is not to exceed 0.08 in H 2 O (20 Pa) over any portion of the test sample. 11.4 The test is to be continued until the exposure period of the classification or rating being evaluated is reached. 11.5 The fire endurance test shall follow the fire exposure as referenced in Section 4. 12 Hose Stream Test 12.1 Immediately after and within 3 minutes of the end of the Fire Endurance Test, Section 11, the test assembly is to be subjected to the impact, erosion, and cooling effects of a hose stream directed first at the bottom center and then at all parts of the exposed surface. The hose stream is to be applied with a smooth steady movement of the hose at a rate to ensure all parts of the test assembly are impacted by the hose stream. When all parts of the test assembly have been impacted by the hose stream, the application pattern is to be reversed. See Appendix B for a description of the pattern. 12.2 The hose stream is to be delivered through a 2-1/2 in (63.5 mm) hose discharging through a play pipe as described in the Standard for Play Pipes for Water Supply Testing in Fire Protection Service, UL 385. The minimum water pressure at the base of the play pipe and the minimum duration of application in seconds per ft 2 (s/m 2 ) of exposed area are to be as prescribed in Table 12.1.

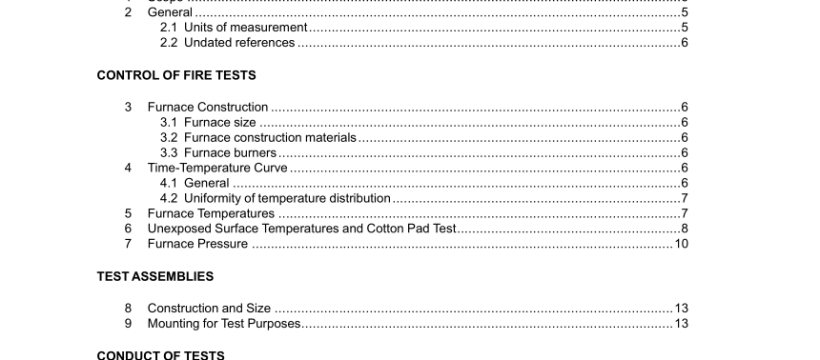

7.4 Data recording is to provide monitoring of the output of an electric pressure transducer in the range of ±0.25 in H 2 O (66 Pa) with an accuracy of ±1 percent. The pressure transducers are to be located within 3 ft (914 mm) vertically, and 10 ft (3048 mm) horizontally from the static probes outside the furnace. 7.5 Pressures are to be read at intervals not exceeding 1 minute. 7.6 The oxygen percentage is to be determined by centering a minimum of one 1/4-in (6.4-mm) inside diameter stainless steel tube containing eight 1/16-inch (1.6-mm) diameter holes in the damper plenum, approximately half way between the furnace and the exhaust damper. The tube is then to be connected to an oxygen analyzer which has an accuracy of ±2.0 percent in the range of 0 to 10 percent. Locating more than one probe in the plenum and averaging the readings is permitted. 7.7 The oxygen percentages are to be read at intervals not exceeding 1 minute and recorded. TESTASSEMBLIES 8 Construction and Size 8.1 The construction and size of the test door assembly, consisting of single doors, doors in pairs, or specialty doors (such as Dutch doors, double-egress doors, and the like), frame and hardware, shall be representative of that for which the classification or rating is being evaluated. 8.2 A floor structure shall be provided as part of the opening to be protected, except where such floor interferes with the operation of the door. The floor segment shall be of noncombustible material and shall project into the furnace approximately twice the thickness of the test door or to the limit of the frame, whichever is greater. 9 Mounting for Test Purposes 9.1 Swinging doors, except as specified in 9.4 and 9.5, shall be mounted so as to open into the furnace chamber. 9.2 The mounting of all doors shall be such that they fit within the frame. Such mounting shall not prevent free and easy operation of the test door.UL 10C-2021 pdf download.

UL 10C-2021 pdf download