UL 4-2021 pdf download.Armored Cable.

5.4.2 Conductors in Type ACHH cable 5.4.2.1 All thermoset-insulated conductors (plus any uninsulated grounding conductor with or without a paper covering) in armored cable shall have an overall covering of fibrous material applied directly over the grouped conductors in the cable. The overall fibrous covering shall be continuous and of a uniform cross section, and shall be at least 5 mils or 0.13 mm thick where 25-mil or 0.64-mm armor is employed and shall be at least 8 mils or 0.20 mm thick where 34-mil or 0.86-mm armor is employed. All fibrous coverings shall be saturated with a preservative and moisture-resistant compound. 5.4.3 Conductors in Type ACTH and ACTHH cable 5.4.3.1 Each insulated circuit conductor and any insulated grounding conductor in a Type ACTH or ACTHH armored cable shall have an individual fibrous covering applied directly over the finished insulated conductor. The covering shall be of paper and shall comply with the thickness, saturation, and application requirements in 5.4.1.1. 5.4.3.2 In addition to having the covering required in 5.4.1 on each of its thermoplastic-insulated conductors, a Type ACTH or ACTHH cable that is provided with an uninsulated grounding conductor without a paper covering shall have an overall covering of fibrous material applied directly over the grouped circuit and grounding conductors to keep the bare conductor from contacting the armor. The overall fibrous covering shall be continuous and of a uniform cross section and shall consist of a strip of unreinforced 30-lb or 47-g/m 2 or heavier kraft paper that is at least 5 mils or 0.13 mm thick and is applied helically with an overlap of at least 50 percent. The paper shall be saturated with a preservative and moisture-resistant compound.

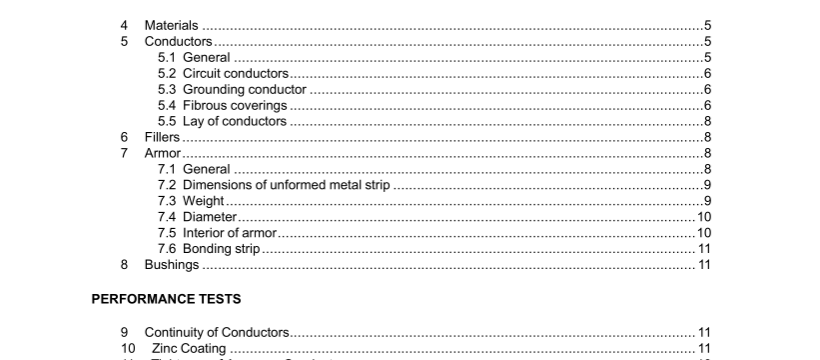

7.2 Dimensions of unformed metal strip 7.2.1 The strip shall be made of an aluminum-base alloy with a copper content of 0.40 percent or less, or of steel. Steel strip shall be made corrosion-resistant by a coating of zinc (see Section 10) on all surfaces, including edges and splices. The coating on each surface shall be evenly distributed, shall adhere firmly at all points, and shall be smooth and free from blisters and all other defects that can diminish the protective value of the coating. 7.2.2 The strip shall be uniform in width, thickness, and cross section and shall not have any burrs, sharp edges, pits, scars, cracks, or other flaws that can damage the underlying cable. Splices shall not materially increase the width or thickness of the strip nor shall they lessen the mechanical strength of the strip or adversely affect the formed armor. 7.2.3 The metal strip shall not be wider or thinner than indicated in Table 7.1. The thickness and width of the strip are to be measured before forming. Measurements are to be made by means of a machinist’s micrometer caliper having an anvil and spindle that are round and are not larger than 0.200 inch or 5.1 mm in diameter, with flat surfaces on each.

7.6 Bonding strip 7.6.1 Armored cable shall have an uninsulated bonding strip located between the conductor assembly and the armor throughout its entire length. The bonding strip, which enhances the grounding ability of the interlocked armor, shall be of aluminum and shall not be smaller than 16 AWG. 8 Bushings 8.1 The construction of armored cable shall be such that an acceptable insulating bushing or its equivalent protection can be inserted readily between the conductors and the armor at each termination of the armor.8.3 Insulating bushings supplied with armored cable, shall be intended for the purpose and shall be of a readily distinguishable bright color such as red, orange, or yellow. At least 35 bushings shall accompany each 250-ft or 75-m length. PERFORMANCE TESTS 9 Continuity of Conductors 9.1 All of the circuit conductors and any grounding conductor in armored cable shall be continuous throughout. Finished cable shall be tested for continuity of each 14 – 10 AWG conductor by the cable manufacturer at the cable factory.UL 4-2021 pdf download.

UL 4-2021 pdf download