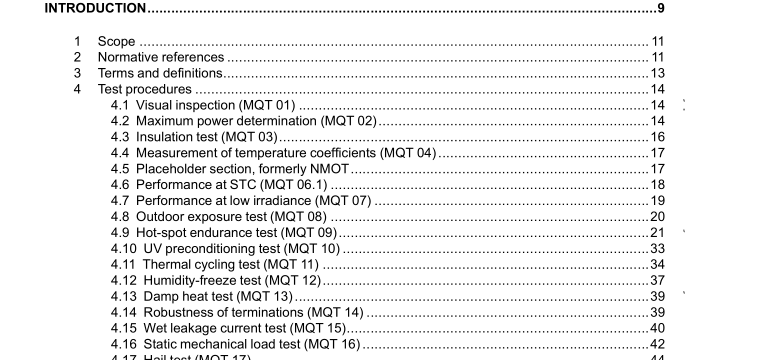

UL 61215-2-2021 pdf download.Terrestrial Photovoltaic (PV) Modules – Design Qualification and Type Approval – Part 2: Test Procedures.

This document is intended to apply to all terrestrial flat plate module materials such as crystalline silicon module types as well as thin-film modules. This document does not apply to modules used with concentrated sunlight although it may be utilized for low concentrator modules (1 to 3 suns). For low concentration modules, all tests are performed using the irradiance, current, voltage and power levels expected at the design concentration. The objective of this test sequence is to determine the electrical characteristics of the module and to show, as far as possible within reasonable constraints of cost and time, that the module is capable of withstanding prolonged exposure outdoors. Accelerated test conditions are empirically based on those necessary to reproduce selected observed field failures and are applied equally across module types. Acceleration factors may vary with product design and thus not all degradation mechanisms may manifest. Further general information on accelerated test methods including definitions of terms may be found in IEC 62506. Some long-term degradation mechanisms can only reasonably be detected via component testing, due to long times required to produce the failure and necessity of stress conditions that are expensive to produce over large areas. Component tests that have reached a sufficient level of maturity to set pass/fail criteria with high confidence are incorporated into the IEC 61215 series via addition to Table 1 in IEC 61215- 1:2021. In contrast, the tests procedures described in this series, in IEC 61215-2, are performed on modules.

4.2.3 Procedure Determine the current-voltage characteristic of the module in accordance with IEC 60904-1 at a specific set of irradiance and temperature conditions (a recommended range is a cell temperature between 20 °C and 50 °C and an irradiance between 700 W/m 2 and 1 100 W/m 2 ) using the apparatus described in 4.2.2. In special circumstances when modules are designed for operation under a different range of conditions, the current-voltage characteristics can be measured using temperature and irradiance levels similar to the expected operating conditions. For linear modules (as defined in IEC 60904-10) temperature and irradiance corrections can be made in accordance with IEC 60891 in order to compare sets of measurements made on the same module before and after environmental tests. For nonlinear modules (as defined in IEC 60904-10) the measurement shall be performed within ±5 % of the specified irradiance and within ±2 °C of the specified temperature. However, every effort should be made to ensure that peak power measurements are made under similar operating conditions, that is minimize the magnitude of the correction by making all peak power measurements on a particular module at approximately the same temperature and irradiance. For flexible modules, the maximum power determination shall be measured with the flexible module in the flat position.

4.3.2 Apparatus a) DC. voltage source, with current limitation, capable of applying the voltage as specified in the third column of Table 1 for the various module classes. b) An instrument to measure the insulation resistance. 4.3.3 Test conditions The test shall be made on modules at ambient temperature of the surrounding atmosphere (see IEC 60068-1) and in a relative humidity not exceeding 75 %. The voltage stress levels applied to the module are determined by the module’s maximum system voltage (V sys ), the module class, and whether or not cemented joints are present. The definitions of module classes are taken from IEC 61140, and are discussed as related to PV modules in IEC 61730-1:2016, Clause 4. The definition of cemented joints is given in IEC 61730-1:2016, 3.4.2, and is further discussed in IEC 61730-1:2016, Clauses B.5 and B.9. The voltage stress levels applied in this test are the same as those applied for IEC 61730 2 MST 16. 4.3.4 Procedure a) Connect the shorted output terminals of the module to the positive terminal of a DC insulation tester with a current limitation. b) Connect the exposed metal parts of the module to the negative terminal of the tester. If the module has no frame or if the frame is a poor electrical conductor, wrap a conductive foil around the edges. Connect all foil covered parts to the negative terminal of the tester.UL 61215-2-2021 pdf download.

UL 61215-2-2021 pdf download