UL 746B-2019 pdf download.Polymeric Materials – Long Term Property Evaluations.

I Scope

1 .1 These requirements cover long-term test procedures to be used for the evaluation of materials used for parts intended for specific applications in end products.

1.2 Together with the Standards mentioned in Supplementary Test Procedures, Section , these investigations provide data with respect to the physical, electrical, flammability, thermal, and other properties of the materials under consideration and are intended to provide guidance for the material manufacturer, the molder, the end-product manufacturer, safety engineers, and other interested parties.

2 References

2.1 Any undated reference to a code or standard appearing in the requirements of this standard shall be

interpreted as referring to the latest edition of that code or standard.

3 Supplementary Test Procedures

3.1 The Standard for Tests for Flammability of Plastic Materials for Parts in Devices and Appliances, UL

94, covers flammability of polymeric materials used for parts in devices and appliances. The Standard for Polymeric Materials — Short Term Property Evaluations, UL 746A, contains short-term test procedures to be used for the evaluation of materials used for parts intended for specific applications in electrical end products. The Standard for Polymeric Materials — Fabricated Parts, UL 746D, contains requirements for traceability and performance of parts molded and fabricated from polymeric materials.

3.2 Programs for the investigation of material part modifications, such as the plating of plastics or the use of flame-retardant paints, are contained in the Standard for Polymeric Materials — Use in Electrical Equipment Evaluations, UL 746C.

3.3 Data concerning the effect of various environments and contaminants upon the properties of materials can also be obtained through standard test procedures. The more commonly used procedures are briefly described in the Standard for Polymeric Materials — Short Term Evaluations, UL 746A.

3.4 Test procedures are provided in the Standard for Polymeric Materials — Use in Electrical Equipment

Evaluation, UL 746C, for the evaluation of polymeric materials in specific applications in end products.

These test procedures include references to the data obtained from the standard property tests as well as

other practical means of evaluation.

3.5 Requirements for materials that have been modified to match the requirements of a specific application, including the use of recyded and regrind materials, the use of additives and colorants, and the blending of two or more materials, are described in the Standard for Polymeric Materials — Fabricated Parts, UL 7460.

4 CharacterIstics of Polymeric Materials

4.1 Polymeric materials include thermoplastic. thermosetting, and elastomenc materials. A thermoplastic material can be easily softened and resoftened by repeated heating. A thermosetting material cures by chemical reaction and, when cured, cannot be resoftened. An elastomeric material is capable of being stretched at room temperature to at least twice its length under low stress and recovers to its original length when released from the stress.

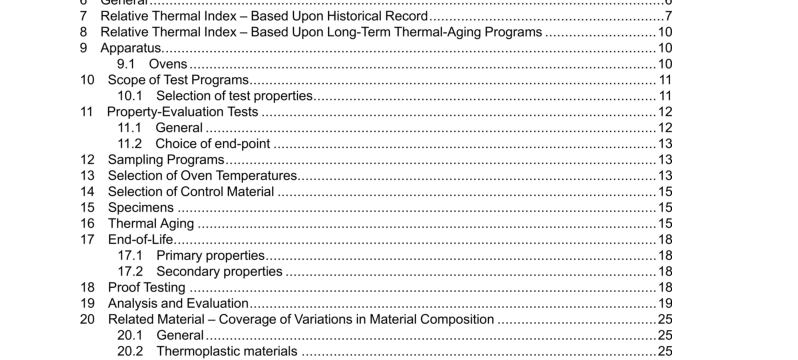

6.3 The relative thermal index of a material is to be based upon an evaluation of long-term thermal-aging data obtained under the program described in Relative Thermal Index – Based Upon Long-Term Thermal- Aging Programs, Section 8. Thermal indices on a generic basis have been established through knowledge of extensive field-service records, as outined in Relative Thermal Index – Based Upon Historical Record, Section 7. Relative thermal indices may also be established based upon a study and evaluation of the interrelationship of all of the data mentioned in Supplementary Test Procedures, Section 3, which can also be coupled with knowledge concerning the material’s performance in insulating systems gained through experience or long-term aging tests. 6.4 A comparison of the thermal-aging characteristics of one material of proven field service at a particular temperature level with the thermal-aging characteristics of another material with no field service history provides a means for estimating the relative thermal index level at which the second material might also provide acceptable field service. 6.5 Another explanation of a relative thermal index is the maximum temperature below which a material maintains its characteristics over a reasonable period. This relative thermal index serves the very great need to evaluate materials that are exposed to heat sources in electrical products in which they are not used as part of an insulating system and in which they are not subjected to other major degradation infuences. It is to be assumed that neither excessively long nor excessively short duty cycles are involved.UL 746B-2019 pdf download.

UL 746B-2019 pdf download