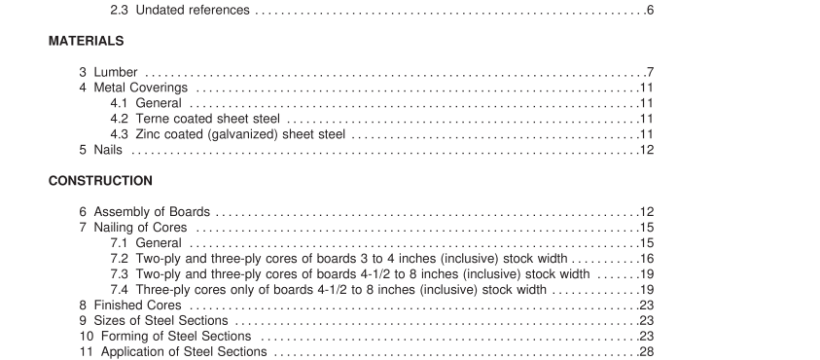

UL 10A-2009 pdf download.Tin-Clad Fire Doors.

3.6 The actual thickness of the boards shall be not less than 3/4 in (1 9.1 mm). 3.7 The boards shall not be less than 4 in (89 mm) nor more than 8 in (1 78 mm) in nominal width. 3.8 The nominal width (or stock width) is greater than the actual width over the tongue and groove. 3.9 The boards shall be free from wane (bark), decay, knot or other holes, loose knots, unsound knots, or knots exceeding 2-1 /2 in (64 mm) in any dimension. 3.1 0 Lumber of a No. 2 Common or Construction grade or better will meet these requirements. However, because some pieces of No. 2 grade are unacceptable, the kind of lumber used and its condition shall be judged from characteristic properties of the wood as commonly known. These characteristics include: a) DECAY – Destruction of the wood substance due to the action of wood-destroying fungi; Note: ″Dote″ and ″rot″ are synonymous with ″decay″ and are any form of decay which is evident either as a dark red discoloration, not found in the sound wood, or the presence of white or red rotten spots. b) ADVANCED (Typical) DECAY – The older stage of decay in which the destruction is readily recognized because the wood has become punky, soft and spongy, stringy, ring shaped, pitted, or crumbly; c) INCIPIENT DECAY – The early stage of decay which has not proceeded far enough to soften or otherwise perceptibly impair the hardness of the wood; d) KNOT – That portion of a branch which has become incorporated in the body of a tree; e) LOOSE KNOT – A knot which is not firmly held in place by growth or position; f) TIGHT KNOT – A knot so fixed by growth or position that it firmly retains its place in the wood piece; g) HOLLOW KNOT – A hollow knot is an apparently sound knot except it contains a hole over 1 /4 in (6.4 mm) in diameter or a void area behind the knot; h) CHECK – A separation along the grain, the greater part of which occurs across the rings of annual growth; i) WANE – The lack of wood from any cause, or bark on the surface of lumber.

3.1 1 To permit judging of the several characteristics of knots, such are to be measured across their lines of growth for oval and circular knots. For spike knots the measurement is to be parallel to the lines of growth. In all cases the measured distance is to be the visible portion of the knot and is normally darker or lighter than the coloring of board. 3.1 2 The following characteristics are to be judged as unacceptable: a) Oval, circular, or spike knots exceeding 2-1 /2 in (64 mm) in any direction (D or L), as shown in Figure 3.1 . b) Loose knots, open knots, or any knot over 1 in (25.4 mm) in any direction located on the tongue or lip.

4 Metal Coverings 4.1 General 4.1 .1 The terne or zinc-coated steel sections shall have straight edges and square corners when a deviation from a square does not exceed 1 /32 in per ft (2.7 mm/m) and is true with straight joints and does not require patching of the rows of sheets in the covering. 4.2 Terne coated sheet steel 4.2.1 Terne coating shall be understood as indicating an alloy coating of tin and lead hot-dipped applied. The terne coating shall be uniformly applied to both sides of sheet steel having an uncoated thickness of not less than 0.01 0 in (0.25 mm). The terne coating shall not crack, peel, or flake when formed. 4.2.2 The coating shall be in conformance with the coating designation LT55 in Table I of ASTM A308, Specification for Steel Sheet, Terne (Lead-Tin Alloy) Coated by the Hot-Dip Process : not less than 0.55 oz/ft 2 (1 68 g/m 2 ) average weight of coating (total both sides) by triple spot test and not less than 0.40 oz/ft 2 (1 22 g/m 2 ) of terne coating (total both sides) by the single spot test, with not less than 40 percent of the coating on any side, based on the single spot test requirement in ASTM A308. Material that is less than 1 8 in (457 mm) wide is subject to the single spot test and 40 percent per side minimum requirements only. The weight of terne coating is determined by any method; however, in case of question the weight of terne coating shall be established in accordance with Procedure D of the test method of ASTM A309, Standard Test Method for Weight and Composition of Coating on Terne Sheet by the Triple-Spot Test. 4.3 Zinc coated (galvanized) sheet steel 4.3.1 Zinc coated (galvanized) sheet steel shall have an uncoated thickness of not less than 0.01 0 in (0.25 mm). The zinc coating shall not crack, peel, or flake when formed. UL 10A-2009 pdf download.

UL 10A-2009 pdf download