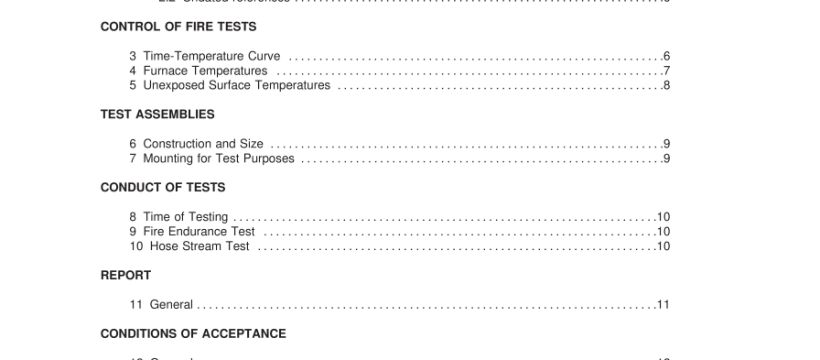

UL 10B-2009 pdf download.Fire Tests of Door Assemblies.

4 Furnace Temperatures 4.1 The temperatures of the test exposure shall be deemed to be the average temperature obtained from the readings of not less than nine thermocouples symmetrically disposed and distributed to show the temperature near all parts of the test assembly, see Figure 4.1 . The thermocouple assembly is to consist of a thermocouple protected by a sealed porcelain tube having a 3/4 inch (1 9.1 mm) outside diameter and 1 /8 inch (3.2 mm) wall thickness or, a base-metal thermocouple, protected by: (1 ) a 1 /2-inch (1 2.7-mm) wrought-steel or wrought-iron pipe of standard weight or (2) Inconel 600 series schedule 40 pipe (0.8 inch OD / 0.6 inch ID, 20 mm OD / 1 5 mm ID). The end of the thermocouple assembly is to be initially located 6 inches (1 52 mm) from the exposed face of the door assembly or from the wall assembly in which the door assembly is installed. During the fire exposure, if the movement of the test sample causes the sample’s distance to the end of the thermocouple assembly to vary, the end of the thermocouple assembly is to be reset to 6 inches (1 52 mm) at intervals not exceeding 1 0 minutes during the first 30 minutes of the test. Thereafter, the intervals are to be increased to not more than 30 minutes. 4.1 revised April 1 3, 2009 4.2 The temperatures are to be recorded at intervals not exceeding 1 minute. 4.3 The accuracy of the furnace control is to be such that the area under the time-temperature curve, obtained by averaging the results from the thermocouple readings, is within 1 0 percent of the corresponding area under the standard time-temperature curve for fire tests of 1 hour or less duration or during the first hour of multi-hour tests, 7.5 percent in the first 2 hours of multi-hour tests, and within 5 percent for tests exceeding 2 hours in duration.

7.1 0 Clearances for horizontal slide-type elevator doors shall be as follows: with a minus 1 /8 inch (3.2 mm) tolerance – 3/8 inch (9.5 mm) between the door and wall surfaces, 3/8 inch (9.5 mm) between multisection door panels, and 3/8 inch (9.5 mm) from the bottom of a panel to the sill. Multisection door panels shall overlap 3/4 inch (1 9.1 mm). Door panels shall overlap the wall opening 3/4 inch (1 9.1 mm) at sides and top. 7.1 1 Door frames shall be evaluated when mounted so as to have the doors open either away from or into the furnace chamber, at the discretion of the testing authority, to obtain representative information on the performance of the construction under test. 7.1 2 Surface-mounted hardware (fire-exit devices) for use on fire doors shall be evaluated by being installed on one door assembly swinging into the furnace chamber and another door assembly swinging away from the furnace chamber. 7.1 3 Door frame wall anchors, when used, shall be intended for the wall or partition construction. CONDUCT OF TESTS 8 Time of Testing 8.1 Masonry shall possess the strength to retain the assembly securely in position throughout the fire and hose stream test. 9 Fire Endurance Test 9.1 The pressure in the furnace chamber is to be 0 ±0.01 inches of water at the top of the door. 9.2 The test is to be continued until the exposure period of the specified classification or rating is reached unless the conditions of acceptance set forth in Sections 1 2 and 1 3 are exceeded in a shorter period.

10 Hose Stream Test 1 0.1 Immediately after to within 3 minutes from the termination of the fire endurance test, the test assembly is to start to be subjected to the impact, erosion, and cooling effects of a hose stream directed first at the bottom center of the assembly and then at all parts of the exposed surface. The hose stream is to be applied, with a smooth steady movement of the hose at a rate to ensure that all parts of the test assembly are impacted by the hose stream. When all parts of the test assembly have been impacted by the hose stream, the application pattern is to be reversed. See Appendix C for a description of the pattern. 1 0.2 Deliver the hose stream through a 2-1 /2-inch (64.5-mm) hose discharging through a National Standard Playpipe of corresponding size equipped with a 1 -1 /8-inch (28.6-mm) discharge tip of the standard-taper, smooth-bore pattern without shoulder at the orifice. The minimum water pressure at the base of the nozzle and the minimum duration of application in seconds per square foot (s/m 2 ) of exposed area is to be as prescribed in Table 1 0.1 . 1 0.3 The tip of the nozzle is to be located a maximum of 20 feet (6 m) from and on a line normal to the center of the test door. When it is not possible to be so located, the nozzle is to be on a line deviating not more than 30 degrees from the line normal to the center of the test door.UL 10B-2009 pdf download.

UL 10B-2009 pdf download