UL 1004-3-2009 pdf download.Thermally Protected Motors.

5 Glossary 5.1 For the purpose of this standard, the following definitions apply. 5.1 effective September 1 5, 201 4 5.2 AUTOMATICALLY RESET PROTECTOR – A device that is calibrated to open the motor circuit upon reaching a certain temperature and automatically closes the circuit once the device has cooled to a lower temperature. 5.2 effective September 1 5, 201 4 5.3 MANUALLY RESET PROTECTOR – A device that is calibrated to open the motor circuit upon reaching a certain temperature and requires a manual action to reclose the motor circuit. 5.3 effective September 1 5, 201 4 5.4 PRIMARY PROTECTOR – A protector that is expected to operate during the abnormal testing of a motor sample. 5.4 effective September 1 5, 201 4 5.5 SELF-HOLDING PROTECTOR – A device that is calibrated to open the motor circuit upon reaching a certain temperature but requires both cool down below the calibration point and removal of power for resetting of the protector. 5.5 effective September 1 5, 201 4 5.5.1 SINGLE-OPERATION DEVICE – A device that is calibrated to open a motor circuit upon being exposed to a defined temperature and which is reset only upon cooling to -35°C (-31 °F) or lower. Added 5.5.1 effective September 1 5, 201 4 5.5.2 THERMAL CUTOFF – A device that is calibrated to open a motor circuit upon being exposed to a defined temperature. Added 5.5.2 effective September 1 5, 201 4 5.6 THERMAL MOTOR PROTECTOR, THERMAL PROTECTOR, OR PROTECTOR – A device installed integrally within a motor that is responsive to motor current and temperature or temperature only and that, when applied as intended, prevents motor overheating. Types are: thermal cutoff, automatically reset, manually reset, self-holding and single-operation. 5.6 effective September 1 5, 201 4 5.7 THERMALLY PROTECTED MOTOR – A motor that relies upon a device (protector) to prevent overheating. 5.7 effective September 1 5, 201 4

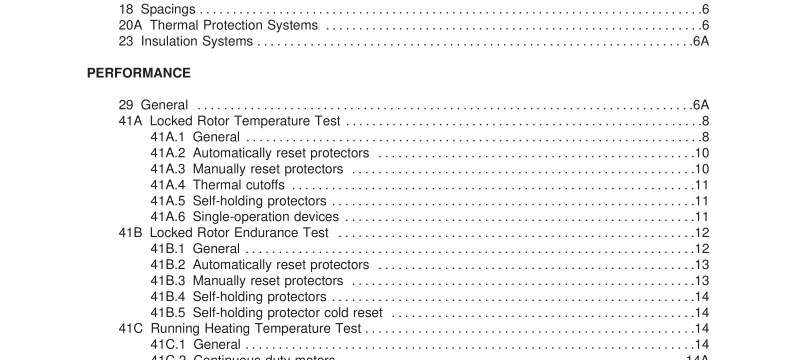

29 General 29.1 A motor that uses alternate types of outer wrap tape or uses alternate bobbin materials shall have each material subjected to the Locked Rotor Temperature Test, Section 41 A, and the Locked Rotor Endurance Test, Section 41 B. Following the tests, the tape and/or bobbin shall not shift or distort to result in a reduction of spacings or to expose uninsulated live parts. 29.1 effective September 1 5, 201 4 29.2 The performance tests are to be conducted on representative samples of motor/protector combinations. The number of samples required to be tested are to be consistent with the range of motors to be protected. 29.2 effective September 1 5, 201 4 29.3 A protector calibrated to have a tolerance in excess of ±5°C (±9°F) of the nominal opening temperature or ±1 5°C (±27°F) of the closing temperature, shall be tested in accordance with 29.4 to determine that the wider tolerance protector has an intended locked-rotor cycling life. 29.3 effective September 1 5, 201 4 29.4 As required by 29.3, the following motor/protector combinations are to be tested to all temperature and endurance requirements as follows: a) One sample protector calibrated to open at the maximum temperature shall be subjected to all tests required in this Standard; and b) One sample calibrated to open at the minimum temperature and close at the maximum temperature shall be subjected to the Locked Rotor Endurance Test, Section 41 B, except the duration is to be 1 8 days. 29.4 effective September 1 5, 201 4 29.5 When a secondary or back-up protector is provided, it shall not operate under any conditions of test. 29.5 effective September 1 5, 201 4

29.6 Polyphase motors shall be provided with protectors so that each phase winding is protected from overheating. 29.6 effective September 1 5, 201 4 29.7 A single-operation device shall not reset itself at a temperature higher than minus 35°C (minus 31 °F). 29.7 effective September 1 5, 201 4 29.8 During the tests, the current is to be monitored and recorded at key events such as when the load is increased during the Running Heating Temperature Test, Section 41 C, or when the protector trips during the Locked Rotor Temperature Test, Section 41 A. Exception: The current is not required to be monitored during the Locked Rotor Endurance Test, Section 41 B. 29.8 effective September 1 5, 201 4 29.9 The primary protector shall operate during the Locked Rotor Temperature Test, Section 41 A, and during the Locked Rotor Endurance Test, Section 41 B. 29.9 effective September 1 5, 201 4 29.1 0 The primary protector shall not operate during the Ratings Tests, Section 30 of UL 1 004-1 , or during the Temperature Test, Section 31 of UL 1 004-1 . 29.1 0 effective September 1 5, 201 4 29.1 1 Manufacturers that choose to provide a thermal motor protector in their impedance protected motor may, at their option, elect to have the motor evaluated to the requirements of this Standard as a thermally protected motor. If so, at the manufacturer’s option, the motor will be either tested at an elevated ambient or be tested at an elevated voltage in either case sufficient to cause the thermal protector to operate under locked rotor conditions and thus the motor to behave as a thermally protected motor. 29.1 1 effective September 1 5, 201 4.UL 1004-3-2009 pdf download.

UL 1004-3-2009 pdf download