UL 144-2021 pdf download.LP-Gas Regulators.

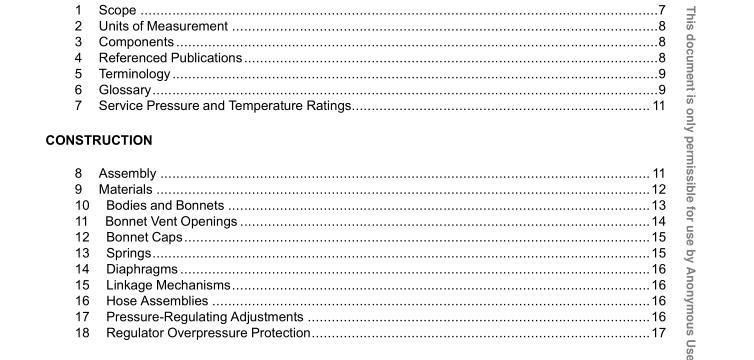

2 Units of Measurement 2.1 Values stated without parentheses are the requirement. Values in parentheses are explanatory or approximate information. 3 Components 3.1 Except as indicated in 3.2, a component of a product covered by this standard shall comply with the requirements for that component. 3.2 A component is not required to comply with a specific requirement that: a) Involves a feature or characteristic not required in the application of the component in the product covered by this standard, or b) Is superseded by a requirement in this standard. 3.3 A component shall be used in accordance with its rating established for the intended conditions of use. 3.4 Specific components are incomplete in construction features or restricted in performance capabilities. Such components are intended for use only under limited conditions, such as certain temperatures not exceeding specified limits, and shall be used only under those specific conditions. 4 Referenced Publications 4.1 The documents shown below are referenced in the text of this Standard. Any undated reference to a code or standard appearing in the requirements of this Standard shall be interpreted as referring to the latest edition of that code or standard. UL Standards UL 252, Standard forCompressed Gas Regulators UL 569, Standard forPigtails and Flexible Hose Connectors forLP-Gas UL 2061, Standard for Adapters and Cylinder Connection Devices for Portable LP-Gas Cylinder Assemblies

6.7 REGULATOR: a) AUTOMATIC CHANGEOVER REGULATOR – An integral two-stage regulator that combines two high-pressure regulators and a second-stage regulator into a single unit. It incorporates two inlet connections that is designed for use with dual or multiple cylinder installations. The system automatically changes the LP-Gas vapor withdrawal from the designated service cylinder(s) to the designated reserve cylinder(s) without interruption of service. It incorporates a service-reserve indicator or provision for attachment of a service-reserve indicator. The service-reserve indicator gives a visual indication of the cylinder(s) that are supplying the system. A switching device is manually selected to alternate between the service and reserve cylinders. b) FIRST-STAGE REGULATOR – A type of high-pressure regulator for LP-Gas vapor service designed to reduce pressure from the container to a nominal pressure of 13.7 – 68.7 kPa (2 – 10 psig). c) HIGH-PRESSURE REGULATOR – A pressure regulator for LP-Gas liquid or vapor service designed to reduce pressure from the container to a lower pressure in excess of 6.9 kPa (1.0 psig). d) INTEGRAL 13.8 KPA (2 PSIG) SERVICE REGULATOR – A pressure regulator that combines a high-pressure regulator and a 13.8 kPa (2 psig) 13.8 kPa (2 psig)service regulator into a single unit. e) INTEGRAL TWO-STAGE REGULATOR – A pressure regulator that combines a high-pressure regulator and a second-stage regulator into a single unit. f) MANUAL CHANGEOVER REGULATOR – A single-stage regulator with a manifold that contains two inlets that allow LP-Gas to flow from one inlet or the other using a handle or lever through the single-stage regulator to the gas consuming equipment. It is designed to be used with two LP-Gas containers. When the supply is exhausted from one container, the lever or handle must be manually moved to allow LP-Gas to flow from the second container.

6.8 SERVICE-RESERVE INDICATOR – A device that gives a visual indication when the regulator system has switched from the designated “service” cylinder to the designated “reserve” cylinder. 6.9 VALVE: a) TYPE I RELIEF VALVE – A valve that is constructed to relieve pressure resulting from seat leakage due to the inability of the seat mechanism to achieve lock-up. b) TYPE II RELIEF VALVE – A valve that has a start-to-discharge setting in accordance with Table 18.1 and is constructed to limit regulator outlet pressure to 13.8 kPa (2 psig) [for second-stage, integral two-stage and automatic changeover regulators when used as part of a two-stage regulator system] or 34.5 kPa (5 psig) [for 13.8 kPa (2 psig) service and integral 13.8 kPa (2 psig) 13.8 kPa (2 psig)service regulators when used as part of a 13.8 kPa (2 psig) regulator system] when tested in accordance with the Type II Relief Valve Flow Capacity Test, Section 31. 7 Service Pressure and Temperature Ratings 7.1 The maximum inlet pressure rating of a single-stage regulator, first-stage regulator, high-pressure regulator, integral two-stage regulator, or integral 13.8 kPa (2 psig) service regulator shall not be less than 1723.7 kPa (250 psig). 7.2 The maximum inlet pressure rating for a second-stage regulator or 13.8 kPa (2 psig) service regulator shall be 68.9 kPa (10 psig). 7.3 Regulators shall meet all of the requirements of this standard when exposed to ambient temperatures within the range of -40°C – +55°C (-40°F – +130°F).UL 144-2021 pdf download.

UL 144-2021 pdf download