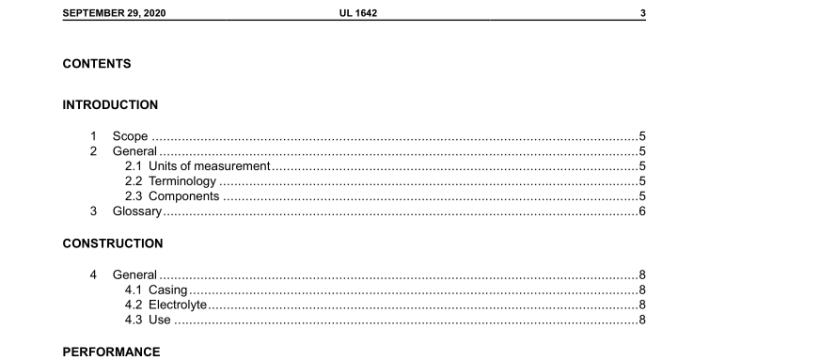

UL 1642-2020 pdf download.Lithium Batteries.

10 Short-Circuit Test 10.1 Each test sample battery, in turn, is to be short-circuited by connecting the positive and negative terminals of the battery with a circuit load having a resistance load of 80 ±20 mΩ. The temperature of the battery case is to be recorded during the test. The battery is to discharge until a fire or explosion is obtained, or until it has reached a completely discharged state of less than 0.2 V and the battery case temperature has returned to ±10°C (±18°F) of ambient temperature. The voltage at the end of the test may not reach 0.2 V due to operation of protective devices in the circuit. The return to near ambient of the battery (cell) casing in an indication of ultimate results. 10.2 Tests are to be conducted at 20 ±5°C (68 ±9°F) and at 55 ±5°C (131 ±9°F). The batteries are to reach equilibrium at 20 ±5°C or 55 ±5°C, as applicable, before the terminals are connected. 10.3 A battery is to be tested individually unless the manufacturer indicates that it is intended for use in series or parallel. For series or parallel use, additional tests on five sets of batteries are to be conducted using the maximum number of batteries to be covered for each configuration. 10.4 When an overcurrent protective device activates during the test, the test shall be repeated with the battery supply connected to the maximum load that does not cause the protective device to open. Protective devices that are relied upon to meet the compliance criteria for the short circuit test shall comply with 2.3.1. 10.5 The samples shall not explode or catch fire.

Exception: At the manufacturer’s discretion, test currents greater than the specified three times rated I c can be applied to expedite the test timeframe, with the minimum charging time as 7 h. 11.4 When a non-resettable overcurrent or protective device operates during the test, the test is to be repeated at a charge current below the level that the protective device operates. When a resettable protective device operates during the test, the protector is allowed to reset to a total of 10 cycles; or until the appropriate charging time has been completed, but not less than 7 h. Protective devices that are relied upon to meet the compliance criteria for the abnormal charging test shall comply with 2.3.1. 11.5 The samples shall not explode or catch fire. 11.6 Secondary cells or batteries shall comply with 11.7 – 11.10. 11.7 Cells or batteries conditioned in accordance with Table 6.2, as applicable, are to be used for this test. The batteries are to be tested in an ambient temperature of 20 ±5°C (68 ±9°F). 11.8 Each test sample battery is to be discharged at a constant current of 0.2 C/1 h, to a manufacturer specified discharge endpoint voltage. The cell or battery is then to be charged with a constant maximum specified output voltage and a current limit of three times the maximum charging current, I c , specified by the manufacturer. Charging duration is to be 7 h or the time required to reach the manufacturer’s specified end-of-charge condition, whichever is greater. 11.9 When a non-resettable overcurrent or protective device operates during the test, the test shall be repeated at an overcharging current below the level that the protection device operates. When a resettable protective device operates during the test, the protector is to be allowed to reset to a total of 10 cycles; or until the appropriate charging time has been completed, but not less than 7 h.

12 Forced-Discharge Test 12.1 This test is intended for cells that are to be used in series-connected, multicell applications, such as battery packs. 12.2 A fully discharged cell is to be force-discharged by connecting it in series with fully charged cells of the same kind. The number of fully charged cells to be connected in series with the discharged cell is to equal the maximum number less one of the cells to be covered for series use. Five cells are to be fully discharged, at room temperature. 12.3 Once the fully discharged cell is connected in series with the specified number of fully charged cells the resultant battery pack is to be short circuited. 12.4 The positive and negative terminals of the sample are to be connected with a resistance load of 80 ±20 mΩ. The sample is to discharge until a fire or explosion is obtained, or until it has reached a completely discharged state of less than 0.2 V and the battery case temperature has returned to ±10°C (18°F) of ambient temperature. The voltage at the end of the test may not reach 0.2 V due to operation of protective devices in the circuit. The return to near ambient of the cell casing is an indication of ultimate results.UL 1642-2020 pdf download.

UL 1642-2020 pdf download