UL 1784-2020 pdf download.Air Leakage Tests of Door Assemblies and Other Opening Protectives.

3.3 AIR LEAKAGE (Q) – The volume of air flowing, per unit of time, through the openings around a closed test sample under a test pressure difference, expressed as cubic feet per minute (m 3 /s). This air leakage volume is to be reported normalized to an ambient air temperature of 75°F (24°C). 3.4 AIR SYSTEM – A controllable blower, compressed air supply, exhaust system, or reversible blower designed to provide a constant required air flow at the specified fixed test pressure difference for the period required to obtain readings of air leakage. 3.5 AMBIENT TEMPERATURE EXPOSURE – The temperature at the exposed face of the test sample is to be 75 ±20°F (24 ±11°C). 3.6 ELEVATED TEMPERATURE EXPOSURE – The temperature at the exposed face of the test sample is to be 400 ±10°F (204 ±5°C). 3.7 EXTRANEOUS LEAKAGE (Q L ) – The difference between the metered air flow (Q m ) and the air leakage (Q). 3.8 METERED AIR FLOW (Q m ) – The volume of air flowing per unit of time through the air flow metering system, expressed as cubic feet per minute (m 3 /s). 3.9 OPENING – The clear area within the test sample boundaries, which may include the floor, header, and other edges that allows the passage of people or materials, determined by the overall dimensions of the test sample expressed as square feet (m 2 ). The floor shall be considered as part of the opening when the frame is not continuous and terminates at the floor slab. 3.10 OPENING PROTECTIVE – A device or assembly such as a curtain used to protect openings in walls against the spread of smoke within, into or out of a building. 3.11 RATE OF AIR LEAKAGE – The air leakage per unit of opening, expressed as cubic feet per minute per square feet (m 3 /s per m 2 ) of the test sample.

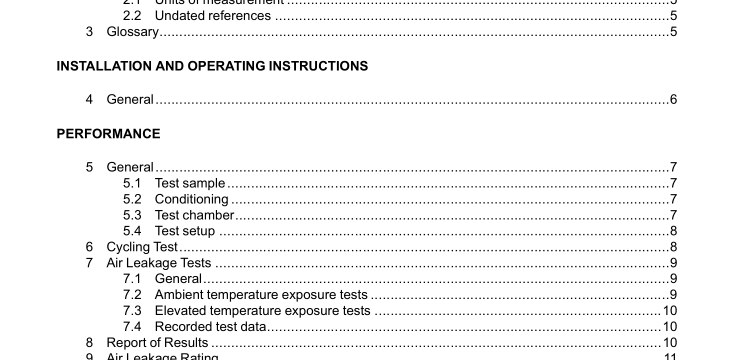

4.2 The instructions shall be used as a guide in the examination and test of the opening assembly. For this purpose, a published edition is not required. A published edition will be required upon successful completion of the test program. 4.3 The evaluated sample size shall be as defined in the Standard for the Installation of Smoke Door Assemblies, NFPA 105. In instances where the test sample or size is not defined in NFPA 105, the construction and size of the tested sample shall be representative of that for which the rating is being evaluated. For test sample sizes not defined in NFPA 105, critical factors including the aspect ratio (ratio of door perimeter to area) and the length of linear gaps or clearances where leakage could occur is to be considered in determining the sample size for testing. The instructions shall be used as a guide in the examination and test of the opening assembly. For this purpose, a published edition is not required. A published edition will be required upon successful completion of the test program. PERFORMANCE 5 General 5.1 Test sample 5.1.1 A representative test sample for each specific design desired for evaluation shall be subjected to the Cycling Test, Section 6, followed by the Air Leakage Tests, Section 7. 5.1.2 Each test sample shall be tested from both directions with respect to the opening of the test chamber. The testing can either be conducted on one test sample that is removed and repositioned in the mounting panel or on two separate, identical test samples. 5.1.3 The test laboratory has the authority to identify and evaluate representative test installations that shall be subjected to the tests described within this standard. When a test sample and assembly is entirely symmetrical about the center plane of the test sample and assembly, a single representative direction can be tested. If testing is conducted from one side only, the justification shall be stated within the report. UL 1784-2020 pdf download.

UL 1784-2020 pdf download