UL 1897-2020 pdf download.Uplift Tests for Roof Covering Systems.

1 Scope 1.1 The test method specified in this Standard is intended to provide uplift resistance data for the evaluation of the attachment of roof covering systems to roof decks by using differential air pressures. It is applicable to any type of roofing system which is adaptable to the test equipment. 1.2 The test evaluates the roof covering systems method of attachment, including all components such as base sheets, ply sheets, slip sheets, membranes, etc. and insulation, if used. Supporting roof decks are evaluated only with respect to span conditions and physical properties such as gauge, yield strength, grade, size and/or species of lumber and related factors which affect fastener attachment or bond strength. 1.3 This test method provides a comparative measure of the uplift resistance for roofing systems by means of static differential pressure. The method does not necessarily simulate the actual dynamic uplift pressures encountered by roofing systems. Uplift pressures on a roofing system are dependent upon many factors such as wind gusts, building shape, edge configuration, and the terrain surrounding the building. A method to calculate the uplift pressures on roof assemblies is contained in the Standard for Minimum Design Loads for Buildings and Other Structures, American Society of Civil Engineers, ANSI/ASCE 7. 1.4 The purpose of this test method is to provide data regarding the securement of the roofing system to the roof deck based upon a short-term static load. When needed the option to include the roof deck attachment to supports shall be described in the test Report. A test method for evaluating uplift resistance of complete roof deck assemblies including the roof deck and its attachment to supports may also be available in Reports for Standard for Tests for Uplift Resistance of Roof Assemblies, UL 580. 2 Units of Measurement 2.1 Values stated without parentheses are the requirement. Values in parentheses are explanatory or approximate information.

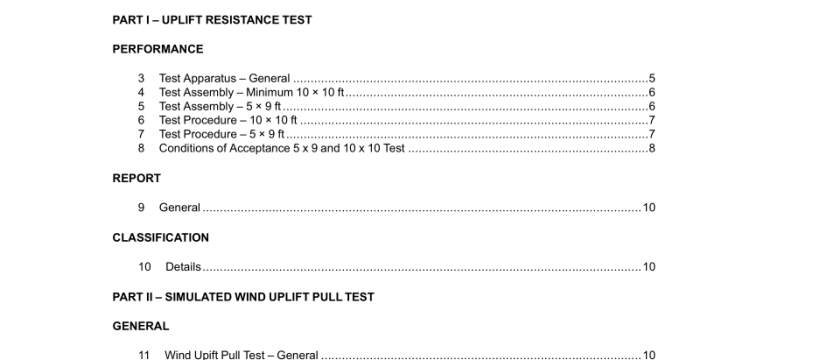

4 Test Assembly – Minimum 10 × 10 ft 4.1 The roof system test assembly is to be representative as to materials, workmanship, and details such as dimensions of parts of the roof deck construction for the rating desired. It shall be built in accordance with the system installation specifications under conditions representative of those in building construction under normal field conditions of use. Properties of the materials and ingredients used in the test assembly, together with their location and method of attachment, are to be determined and recorded. 4.2 The dimensions of the test assembly are to be a minimum of 10 by 10 ft (3.05 by 3.05 m). The test assembly shall contain side and end joints if such occur in field installation, which represent the most vulnerable exposure to uplift due to wind conditions. Test assemblies that utilize mechanically-attached membranes are to be of sufficient size to incorporate a minimum of three batten or fastener rows plus an additional 1-ft ( 0.305-m) minimum outside the outlying batten or fastener rows. The test assembly shall consist of secondary bearing members, such as purlins and joists, to which the roof decking is fastened. The assembly components, including secondary members, are to be located to best simulate field conditions, such as maximum span and maximum attachment spacing. 4.3 The periphery of the roofing system test assembly is to be sealed so as to permit the development of a sustained static pressure differential. 4.4 Polyethylene film shall be permitted to seal joints or other air-permeable portions within roof systems when necessary to attain test pressures. The film shall be applied loosely with longitudinal pleats that are positioned up into ribs and/or with extra folds such that the film follows the contour of the assemblies under test. Use of the plastic film shall not prohibit transfer of the full load to the assembly, shall not prevent full movement, or otherwise adversely impact test results. UL 1897-2020 pdf download.

UL 1897-2020 pdf download