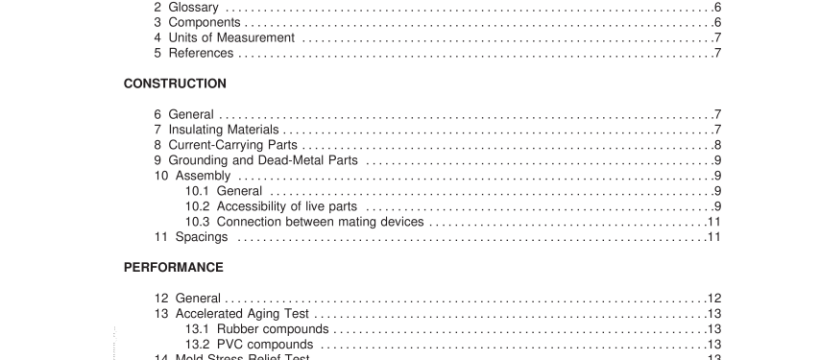

UL 1977-2007 pdf download.Component Connectors for Use in Data, Signal, Control and Power Applications.

9 Grounding and Dead-Metal Parts 9.1 Non-current carrying parts of ferrous metal (other than stainless steel), including mounting screws, shall be protected against corrosion by zinc plating, or an equivalent protective coating. 9.2 Dead metal parts of a device provided with a socket contact identified for use as an equipment-grounding conductor shall be conductively connected to the grounding-conductor path. 9.3 An identified grounding contact, or grounding-conductor path through a device shall be of plated or unplated copper or copper-based alloy. Exception No. 1 : A metal housing, shell or armor of a device in the path of the identified grounding conductor need not be of copper or copper-based alloy, but shall employ a copper or copper-base alloy contact for connection to the housing of a mating device. Exception No. 2: A device mounting means need not be copper or copper-based alloy. Exception No. 3: Other materials may be acceptable if they are found to provide equivalent electrical and mechanical characteristics as a result of special investigation. 10 Assembly 10.1 General 1 0.1 .1 A device shall be capable of being readily installed as intended.

1 0.1 .2 A polarized device incorporating two or more contacts shall be keyed or of such design that the polarization can not be defeated by improper assembly during installation. 1 0.1 .3 Any two or more device parts that may be separated during installation shall not be capable of an assembly that will defeat the intended polarization of wiring. 10.2 Accessibility of live parts 1 0.2.1 A connector of Types 1 A, 2, 3, or 4 intended for usage external to the end equipment shall have live parts protected against exposure to contact by persons when assembled, installed and mated as intended, as determined by the use of the probe shown in Figure 1 0.1 . 1 0.2.2 Mating devices of Types 1 A, 2, 3, or 4 intended for usage external to the end equipment shall not have exposed live contacts during engagement or withdrawal as determined by the use of the probe shown in Figure 1 0.1 .

10.3 Connection between mating devices 1 0.3.1 A hybrid device shall be polarized or otherwise constructed so that contacts with different Type designations cannot make electrical contact when mating devices are connected together. 1 0.3.2 A device provided with an identified grounding contact shall be so constructed that the grounding pin of the corresponding mating device when wired as intended, cannot be inserted into any other opening so as to touch a live contact or other live part. 1 0.3.3 An identified grounding contact provided on a device shall be located and formed so that the path of electrical continuity to the grounding contact of a mating device is completed before continuity is established between any other contact and its respective contact in the mating device. Exception: A Type 0 or 1 B device need not comply with this requirement. 11 Spacings 1 1 .1 For devices as specified in Table 1 1 .1 there shall be a minimum spacing through air and over surface of 1 .2 mm (3/64 inch) for a device rated 250 volts or less, and a minimum of 3.2 mm (1 /8 inch) for a device rated more than 250 volts, between an uninsulated live part and: a) An uninsulated live part of opposite polarity, b) An uninsulated grounded metal part, or c) A non-current carrying metal part that is exposed to contact by persons when the device is installed and used in the intended manner. Exception: Spacings less than those specified are permitted if the device complies with the requirements in the Dielectric Voltage-Withstand Test, Section 1 7.

13 Accelerated Aging Test 13.1 Rubber compounds 1 3.1 .1 A molded-rubber component shall show no apparent deterioration and shall show no greater change in hardness than ten numbers as the result of exposure for 70 hours in a full-draft circulating-air oven at a temperature of 1 00.0 ±2.0°C (21 2.0 ±1 .8°F). 1 3.1 .2 If possible, the complete device is to be tested. The hardness of the rubber is to be determined prior to testing as the average of five readings with an appropriate gauge such as the Rex Hardness Gauge or the Shore Durometer. The device is to be allowed to rest at room temperature for four or more hours after removal from the oven. The hardness is to be determined again as the average of five new readings. The difference between the average original hardness reading and the average reading taken after exposure to the heat conditioning is the change in hardness. 1 3.1 .3 The accelerated-aging tests mentioned in 1 3.1 .1 and 1 3.1 .2 are to be made on each color of rubber and on each basic rubber compound employed for the device.UL 1977-2007 pdf download.

UL 1977-2007 pdf download