UL 2225-2020 pdf download.Cables and Cable-Fittings For Use In Hazardous (Classified) Locations.

1.3 These requirements cover Type TC-ER-HL tray cable for use in hazardous (classified) locations, Class I, Division 1, Groups A, B, C, and D, Zone 1, Groups IIA, IIB, and IIC in accordance with the National Electrical Code, NFPA 70. 1.4 These requirements cover explosionproof and dust-ignitionproof cable sealing fittings for use in hazardous (classified) locations, Class I, Division 1 and 2, Groups A, B, C, and D; Class II, Division 1 and 2, Groups E, F, and G in accordance with the National Electrical Code, NFPA 70. 1.5 These requirements cover explosionproof and dust-ignitionproof cable sealing fittings for Type P cable intended for use on mobile offshore oil rigs and drilling platforms, and other marine vessels, and for use on land-based gas and oil mobile drilling rigs in accordance with the National Electrical Code, NFPA 70-2020. For offshore installations, investigations of these fittings include an evaluation for conformity to the installation and use provisions of Title 46 Code of Federal Regulations Sub-part 111.105 and Subpart 111.60 of the United States Coast Guard Electrical Engineering Regulations, Subchapter J (Parts 110 to 113 inclusive) as applied by the authority having jurisdiction. 1.6 These requirements cover increased safety “e” cable fittings and flameproof “d” cable sealing fittings for use in Zone 1 Groups IIA, IIB and IIC hazardous (classified) locations, in accordance with the National Electrical Code, NFPA 70. 1.7 These requirements cover increased safety “e” cable fittings and flameproof “d” cable sealing fittings for use in hazardous (classified) locations, Zone 1 for use on mobile offshore oil rigs and drilling platforms, and other marine vessels.

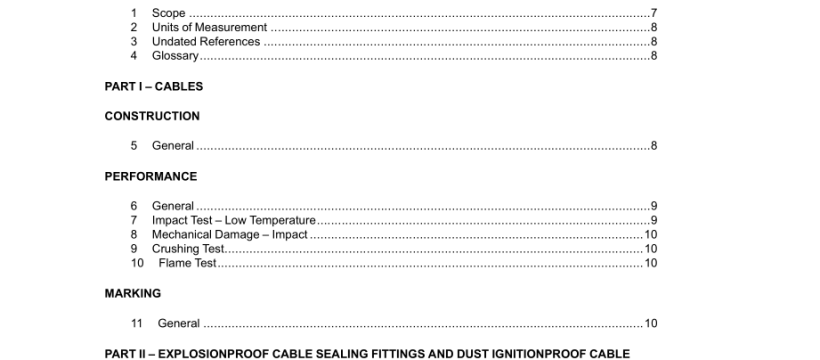

8 Mechanical Damage – Impact 8.1 An Impact Test for all types shall be conducted using the requirements, including sample selection, (cable containing 3 – 14 AWG conductors and 3 – 2 AWG conductors) specified for the Impact Test in the Standard for Metal-Clad Cables, UL 1569 with the exception that the weight of the falling mass shall be 25 pounds (11.34 kg) through a distance of 1 foot (0.31 m) for the tests with the 14 AWG conductors. ITC-HL cables are to be tested only with 14 AWG conductors to represent sizes 22 to 12. ITC-HL cables are permitted to be tested with smaller conductor sizes that represent only the size tested. 9 Crushing Test 9.1 A Crushing Test for all cable types shall be conducted using the requirements specified for the Crushing Test – All Cable, in the Standard for Metal-Clad Cables, UL 1569, with the following modifications. • The sample for non-ITC-HL cables shall contain 3 – 14 AWG conductors and 3 – 2 AWG conductors. • The sample for ITC-HL cables is permitted to contain only 14 AWG conductors (to represent all sizes from 22 AWG to 12 AWG) or small conductor sizes to represent only the size tested. • The crushing force is to be 1500 pound-force (6670 N) for the test with the 14 AWG conductors. 10 Flame Test 10.1 The Flame Test shall be performed in accordance with the FT4/IEEE 1202 Flame Exposure Test in the Standard for Fire-Propagation and Smoke-Release Test for Cables, UL 1685, (smoke measurements are not applicable). 10.2 For MC-HL and ITC-ER-HL, the test specimens for the FT4/IEEE 1202 tray flame test are the smallest size (typically 14/3) [equivalent diameter for a cable that is not round is calculated as 1.1284 × (TW) 1/2 , in which T is the length of the minor axis of the cable and W is the length of the major axis of the cable] cable that the manufacturer intends to produce in each construction made.

12 General 12.1 Explosionproof cable sealing fittings and dust igntionproof cable fittings shall comply with the applicable construction requirements in the Standard for Conduit, Tubing, and Cable Fittings, UL 514B, in addition to the construction requirements in this standard. Where requirements conflict, the requirements in this standard shall apply. 12.2 Design tolerances of the cable sealing fitting shall be considered in determining compliance with 12.1 of this standard. 12.3 The width of all joint surfaces or the length of path through or across any joint surface or opening in the cable sealing fitting, including threadless joints and threaded joints, shall be dimensionally measured for compliance with the appropriate requirements contained in 15.1 or in the Standard for Explosionproof and Dust Ignitionproof Electrical Equipment for Use in Hazardous (Classified) Locations, UL 1203, for the specific Class and Group for which the sealing fitting is intended.UL 2225-2020 pdf download.

UL 2225-2020 pdf download