UL 2565-2019 pdf download.Industrial Metalworking and Woodworking Machine Tools.

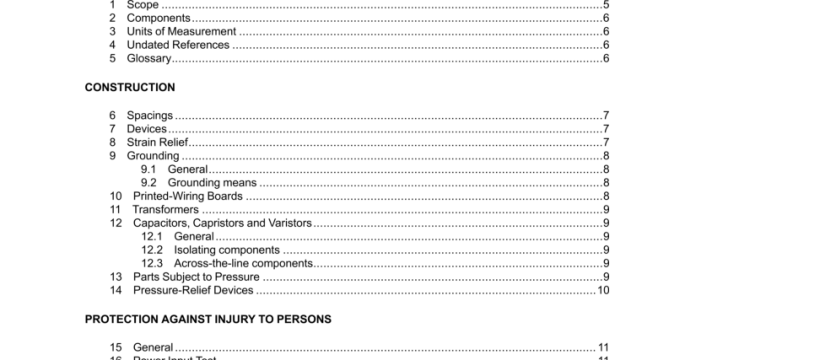

2 Components

2.1 Except as specified in 2.2 and 7.1, a component of a product covered by this standard shall comply with the requirements for that component. See Appendix A for a list of standards covering components generally used in the products covered by this standard.

2.2 A component need not comply with a specific requirement that:

a) Involves a feature or characteristic not needed in the application of the component in the product covered by this standard; or

b) Is superseded by a requirement in this standard.

2.3 A component shall be used in accordance with its rating established for the intended conditions of use.

2.4 Specific components are incomplete in construction features or restricted in performance capabilities. Such components are intended for use only under limited conditions, such as certain temperatures not exceeding specified limits, and shall be used only under those specific conditions.

3 Units of Measurement

3.1 Values stated without parentheses are the requirement. Values in parentheses are explanatory or

approximate information.

4 Undated References

4.1 Any undated reference to a code or standard appearing in the requirements of this standard shall be interpreted as referring to the latest edition of that code or standard.

5 Glossary

5.1 CLASS 2 CIRCUIT — An isolated secondary circuit involving a potential of not more than 30 V (42.4 V peak) supplied by:

a) An inherently-limited Class 2 transformer;

b) A combination of an isolated transformer secondary winding and a fixed impedance or regulating network that together comply with the performance requirements for an inherently limited Class 2 transformer;

C) A dry-cell battery having output characteristics not greater than those of an inherently-limited Class 2 transformer;

d) Any combination of (a), (b), and (c) above that together comply with the performance requirements for an inherently-limited Class 2 transformer; or

e) One or more combinations of a Class 2 transformer and an overcurrent protective device that together comply with the performance requirements for a noninherently-limited Class 2 transformer.

9 Grounding

9.1 General

9.1.1 There shall be provision for grounding the machine and all dead metal parts that are exposed or that are likely to be touched by a person during normal operation or adjustment, and that are likely to become energized through electrical malfunction.

9.1.2 To determine whether a part is likely to become energized, such factors as construction, the proximity of wiring, and a dielectric voltage-withstand test conducted after appropriate overload, endurance, and burnout tests are to be evaluated.

9.1.3 A machine shall comply with the Grounding Resistance Test, Section 30.

9.2 Grounding means

9.2.1 An equipment-grounding terminal or lead-grounding point shall be connected to the frame or enclosure by a positive means, such as by a bolted or screwed connection.

9.21 Nonconductive coatings, such as paint, lacquer, and enamel shall be removed from the grounding surface area to assure electrical continuity, or the grounding connection shall reliably penetrate the nonconductive coating.

9,2.3 A grounding point shall be located so that it is unlikely that the grounding means will be removed during normal servicing.

9.2.4 The following are acceptable means for electrically grounding permanently connected equipment:

a) An equipment-grounding terminal or lead intended to be connected to a nonmetal-enclosed wiring system, for example, a nonmetallic-sheathed cable: and

b) A knockout or equivalent opening in a metal enclosure intended to be connected to a metal enclosed wiring system.

10 Printed-Wiring Boards

10.1 A printed-wiring board shall comply with the Standard for Printed Wiring Boards, UL 796.

10.2 A printed-wiring board containing circuits involving a risk of fire or electric shock shall be rated at least V-2 as specified in requirements for tests for flammability of plastic materials for parts in devices and appliances, Standard for Tests for Flammability of Plastic Materials for Parts in Devices and Appliances, UL 94. Printed-wiring boards not involving a risk of fire or electric shock may be rated HB.

10.3 The laminate material in a printed-wiring board used in a circuit that involves a risk of fire or electric shock shall comply with the direct support of current-carrying parts performance level requirements specified in the Standard for Printed Wiring Boards, UL 796. and be marked with:

a)””; or

b) Have a unique type designation that is limited to such printed-wiring boards to indicate compliance with the direct support requirements of UL 796.

UL 2565-2019 pdf download.

UL 2565-2019 pdf download