UL 2904-2019 pdf download.Standard Method for Testing and Assessing Particle and Chemical Emissions from 3D Printers.

1.2 This method primarily applies to the emissions of particles and volatile organic chemicals from 3D printers and feedstock which are widely used in classrooms, offices, libraries, residential settings, small and medium size enterprises, and other non-industrial indoor spaces. The 3D printers are operated with a variety of commercially available feedstock. For environmental chamber tests under controlled conditions, a 3D printer’s maximum size and format is limited. For measurements, it is required that environmental chamber conditions are known and can be kept stable at least during the measurement. 1.3 The measurement protocols may be used to a) compare emissions from different feedstock or adhesion materials operated by a specific 3D printer, (material impact) b) compare emissions from printing objects of different shape, design, and size on a specific 3D printer (printed object impact) c) compare emissions from different 3D printers operated under identical conditions i. e. same object, same feedstock (print media), same environmental conditions (3D printer hardware impact) d) quantify emissions in a given specific exposure scenario – e.g. workshop, small production line, etc. (environmental impact) e) obtain data for use in risk assessments or product claims 1.4 This method includes requirements on laboratory quality management systems and measurement uncertainty estimation. 1.5 This standard establishes emissions criteria for particles and certain chemicals based on existing standards, guidelines, and research data for the management of airborne gaseous and aerosol pollutants in indoor environments.

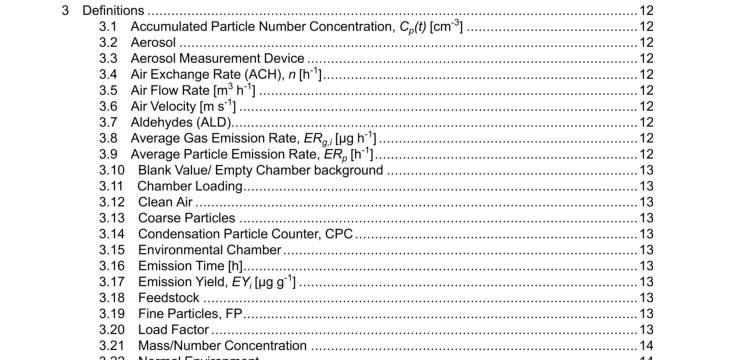

3 Definitions 3.1 Accumulated Particle Number Concentration, C p (t) [cm -3 ] Time-dependent particle number concentration in a specified particle size range (at a minimum between 10 nm and 5 μm). 3.2 Aerosol System of particles (solid and/or liquid) suspended in gas. 3.3 Aerosol Measurement Device For the purposes of this test method, a device for determining the time-dependent particle number concentration of an aerosol within a defined particle size and concentration ranges and with a certain time resolution. 3.4 Air Exchange Rate (ACH), n [h -1 ] Ratio of the volume of clean air at room temperature (see 3.22) and pressure brought into the chamber per hour [m 3 h -1 ] to the unloaded chamber volume [m 3 ]. 3.5 Air Flow Rate [m 3 h -1 ] Air volume at room temperature and pressure entering the environmental chamber per unit time. 3.6 Air Velocity [m s -1 ] The air speed measured in the unloaded environmental testing chamber. 3.7 Aldehydes (ALD) Aldehydes are low molecular weight organic compounds containing a functional group with the structure – CHO. The measured aldehydes are 2-butenal, acetaldehyde, benzaldehyde, 2,5-dimethylbenzaldehyde, 2-methylbenzaldehyde, 3 (and/or) 4-methylbenzaldehyde, butanal, 3-methylbutanal, formaldehyde, hexanal, pentanal, and propanal, individually calibrated to a compound specific standard via High- Performance Liquid Chromatography (HPLC) analysis.

3.11 Chamber Loading Placing a tested 3D printer into the environmental chamber. 3.12 Clean Air Air supplied to the chamber that meets requirements in 8.2 Chamber Parameters. 3.13 Coarse Particles Particles having an aerodynamic diameter greater than 2.5 μm and less than or equal to 10 μm. 3.14 Condensation Particle Counter, CPC Instrument that measures the particle number concentration of an aerosol by condensational growth to optical detection sizes using a working fluid such as water or butanol. For the measurement of total particle number concentration, a CPC with butanol as a working fluid is suggested. 3.15 Environmental Chamber An enclosed test environment consisting of a known volume with controlled environmental parameters used for the purpose of providing accurate and reproducible particle and chemical emission measurements from defined product sources. 3.16 Emission Time [h] Time between when 3D printer starts extruding (t start ) and 3D printer is no longer emitting new particles or 3D printer stops extruding, whichever comes after (t stop ). 3.17 Emission Yield, EY i [μg g -1 ] This quantity gives the mass of the analyte i (VOC or aldehyde) or the number of particles, which is emitted from a tested 3D printer per unit of mass of feedstock used.UL 2904-2019 pdf download.

UL 2904-2019 pdf download