UL 32-2019 pdf download.Metal Waste Cans.

5.3 The thickness of the metal is to be determined by five micrometer readings spaced equally along the edge of the full piece as rolled. Thickness is to be determined on the sheet not less than 3/8 inch (9.5 mm) from a cut edge and not less than 3/4 inch (19.1 mm) from a mill edge. 5.4 A coating of galvanized sheet steel shall comply with the coating designation G60 or A60 in Table 1 of the Standard Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by the Hot-Dip Process, ANSI/ASTM A653/A653M. Not less than 40 percent of the zinc shall be on either side, as determined by the single-spot test described in ANSI/ASTM A653/A653M. The coating shall be free from lumps, blisters, dross, and flux, and shall not flake or peel when formed. 5.5 The weight of coating on terne-coated sheet steel shall be at least as specified for coating designation LT35 in Table 1 of the Standard Specification for Steel Sheet, Terne (Lead-Tin Alloy) Coated by the Hot-Dip Process, ASTM A308. That is, the triple-spot coating weight shall not be less than 0.35 ounce per square foot (0.107 kg/m 2 ) and the single-spot coating weight shall not be less than 0.25 ounce per square foot (0.076 kg/m 2 ). 5.5.1 The weight of a galvanized coating may be determined by any method. However, in case of question, coating weight shall be established in accordance with the Standard Test Method for Weight (Mass) of Coating on Iron and Steel Articles With Zinc or Zinc-Alloy Coatings, ASTM A90/A90M. 5.6 Metal coatings injured or removed in the process of manufacture shall be replaced by solder or aluminum paint. 5.7 Strip steel used for legs and reinforcements shall be painted or plated to retard corrosion.

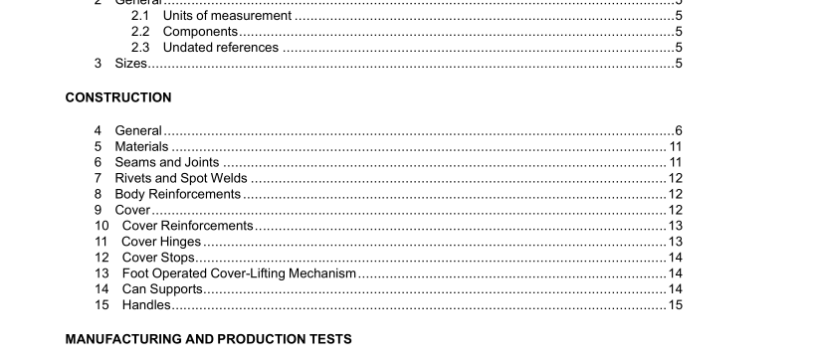

7 Rivets and Spot Welds 7.1 A rivet shall have a shank diameter of not less than 1/8 inch (3.2 mm), and shall not be headed over against sheet metal. If a can is galvanized after forming, an uncoated rivet may be used. 7.2 A rivet shall have a close fit in the rivet hole. 7.3 The head of a rivet on the inside of a waste can within 6 inches (152 mm) of the bottom shall be sweated with solder unless the can is galvanized after the rivet is installed. 7.4 When spot welding is used for the attachment of any part, at least twice the number of welds shall be used as is required for a rivet. Spot welding shall not burn through sheet metal. 8 Body Reinforcements 8.1 The upper edge of the body shall be reinforced by hemming, rolling, wiring, or by some other method that provides stiffness. 8.2 If a waste can is supported by a sheet metal base, the bottom edge of the base shall be reinforced as required for the upper edge of the body. 8.3 A steel strip reinforcement shall be riveted, welded, brazed, or otherwise mechanically secured.

10.3 A one-piece cover shall resist flexing. This may be accomplished by the use of separate reinforcing members or by stamping the cover in such a form that will provide the stiffness indicated in 10.1. 10.4 The movable section of a two-piece cover shall be reinforced by strip steel having a cross-sectional area of not less than 0.109 square inch (0.70 cm 2 ), placed on the center line of the cover at right angles to the hinged edge. See Figure 4.1, Figure 4.2, and Figure 4.3. This reinforcement may be bent up at its outer end at an angle of about 45 degrees to serve as a carrying handle, and the inner end may be bent up to limit the angle of opening. 10.5 The movable section of a two-piece cover shall be further reinforced by two strips of steel, each having a cross-sectional area of not less than 0.093 square inch (0.60 cm 2 ), unless that section is so formed or otherwise constructed that the stiffness is provided. These reinforcing members may be attached to the inside or outside of the cover and shall be placed at an angle of approximately 45 degrees with the center reinforcing member or at right angles to that member. 10.6 Sheet metal, at each point of attachment of the cover stop, shall be reinforced with steel over an area not less than the square of the width of the stop, but not less than 1 square inch (6.45 cm 2 ). Each reinforcement shall have a thickness of not less than one-half the diameter of the shank of holding rivets, but not less than 1/16 inch (1.6 mm). Where a stop strikes the sheet metal, it shall be reinforced to prevent deformation or injury to the coating.UL 32-2019 pdf download.

UL 32-2019 pdf download