UL 330-2021 pdf download.Hose and Hose Assemblies for Dispensing Flammable and Combustible Liquids.

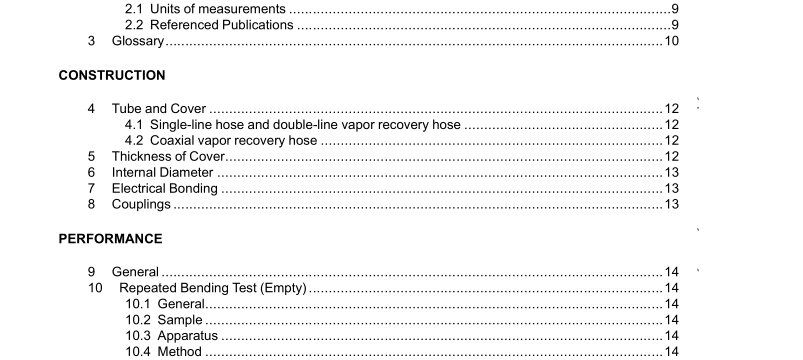

4 Tube and Cover 4.1 Single-line hose and double-line vapor recovery hose 4.1.1 The tube shall be made from a material resistant to gasoline and diesel fuel. 4.1.2 The cover shall be made from a material resistant to gasoline, diesel fuel, oils, and ozone. 4.1.3 The tube and cover shall be of uniform thickness, and free from pitting, blisters, or other imperfections. This requirement is not intended to exclude the use of a corrugated cover. NOTE: This Standard provides requirements for both coaxial vapor recovery hose types where the liquid is conveyed through the inner hose and the vapor is recovered from the outer hose, as well as, vice versa. 4.2 Coaxial vapor recovery hose 4.2.1 The tube and cover, if any, of the inner hose shall be made from materials resistant to gasoline and diesel fuel. 4.2.2 The tube of the outer hose or a homogeneous outer hose shall be made from materials resistant to gasoline and diesel fuel. 4.2.3 The cover of the outer hose or a homogeneous outer hose shall be made from a material resistant to gasoline, diesel fuel, oil, and ozone. 4.2.4 The tube and cover shall be of uniform thickness and free from pitting, blisters, or other imperfections. This requirement is not intended to exclude the use of a corrugated tube, cover, or outer vapor recovery hose.

5 Thickness of Cover 5.1 The thickness of the cover shall not be less than 0.047 in (1.19 mm) when measured in accordance with 5.2 – 5.6. Exception: This requirement does not apply to the cover ofthe inner hose and the outer vapor conveying hose ofa coaxial vaporrecoveryhose. 5.2 For removing irregularities in samples, the buffing machine or skiving machine outlined in the Standard Practice for Rubber – Preparation of Product Pieces for Test Purposes from Products, ASTM D3183, shall be used. 5.3 The abrasive wheel of the buffing machine shall be No. 30 – 60 grit and the diameter and rotary velocity of the wheel shall be such that it will have a peripheral speed of 4000 ±700 ft/min (20.3 ±3.6 m/s). The machine shall be provided with a slow feed so that very little compound can be removed at one cut to avoid overheating of the specimen. 5.4 A dial micrometer graduated to 0.001 in (0.03 mm) that exerts a load of 2.82 – 3.00 oz (80 – 85 g) by means of a weight shall be used to measure thickness. The load shall be applied through a flat contact foot 0.25 ±0.01 in (6.4 ±0.3 mm) in diameter.

5.5 To determine the thickness of the cover, a strip, 6 – 8 in (152.4 – 203.2 mm) long and 1 in (25.4 mm) wide, or as close to 1 in (25.4 mm) as possible from small diameter hose, shall be cut longitudinally from the cover, and the part separated from the plies. When the thickness of the part is not uniform around the circumference of the hose, the strip shall be cut from the thinnest portion of the part. 5.6 The strip specimen shall be buffed or skived to remove the impressions left by the fabric or braid or other surface irregularities, using the equipment described in 5.2 and 5.3. A series of five thickness measurements shall be taken within the area from which the impressions have been removed, and the maximum reading obtained shall be taken as the thickness of the part. 6 Internal Diameter 6.1 The internal diameter of a hose shall be equal to the nominal diameter ±1/32 in (0.8 mm) for sizes up to and including 3/4 in (19.0 mm) and ±1/16 in (1.6 mm) for larger sizes. 6.2 A tapered plug gauge of wood or metal having a taper of 3/8 in/ft (31.3 mm/m), marked to indicate variations of 1/64 in (0.4 mm) in diameter, or a set of wood or metal plug gauges, straight or ball type, in increments no greater than 0.01 in (0.25 mm) for hoses in sizes 1 in (25.4 mm) and less and 0.02 in (0.51 mm) for hoses in sizes greater than 1 in (25.4 mm), shall be used for measuring the internal diameter. An expanding ball gauge, and a micrometer or other equivalent means to accurately measure the expanded ball, are required in some cases. See 6.3.UL 330-2021 pdf download.

UL 330-2021 pdf download