UL 486F-2019 pdf download.Bare and Covered Ferrules.

1.1 These requirements cover bare and covered ferrules intended for field wiring and factory wiring for use in accordance with the National Electrical Code, ANSI/NFPA-70 and Canadian Electrical Code, Part I, CSA C22.1. 1.2 These ferrules are intended to facilitate the connection of stranded wire on to devices, such as terminal blocks. Their purpose is to treat stripped wire and prevent turned back strands during installation. They are intended to be used to attach to one stranded copper conductor or two stranded copper conductors of the same size. 1.3 When intended for use with one conductor, these ferrules are suitable for use with 1/0 – 26 AWG, 50 – 0.14 mm 2 , stranded copper conductors. 1.4 When intended for use with two conductors, these ferrules are suitable for use with (2) 6 – (2) 26 AWG, (2) 16 – (2) 0.25 mm 2 , stranded copper conductors. 1.5 These ferrules are intended to be terminated in wire connection devices rated for solid conductors. 1.6 Ferrules are not intended for use in IDC (insulation displacement connection) terminal blocks. 1.7 This standard does not apply to wire connectors such as pin adapters covered in CSA C22.2 No. 65 or UL 486A-486B. 1.8 In Canada, general requirements applicable to this Standard are provided in CAN/CSA-C22.2 No. 0.

3 Units of Measurement 3.1 The values given in SI (metric) units shall be normative, except for AWG conductor sizes. Any other values given are for information only. 3.2 AWG is the normative wire size of the standard. The mm 2 is the closest equivalent to that size. 4 Definitions For the purpose of this Standard, the following terms and definitions apply. 4.1 Covered – Encased within material of composition or thickness that is not recognized as electrical insulation. 4.2 Covered ferrule – A ferrule provided with a plastic sleeve. 4.3 Ferrule – A conductive sleeve used to facilitate the termination of stranded wire in devices used to terminate solid conductors. 4.4 Plastic sleeve – A non-conductive plastic material used for identification purposes. The term “covering” is also referred to in the Standard as a “plastic sleeve”. 5 Symbols and Abbreviations 5.1 ° – Degree 5.2 AWG – American Wire Gage/gauge 5.3 C – Celsius 5.4 mm 2 – Squared millimeters 5.5 V – Volts

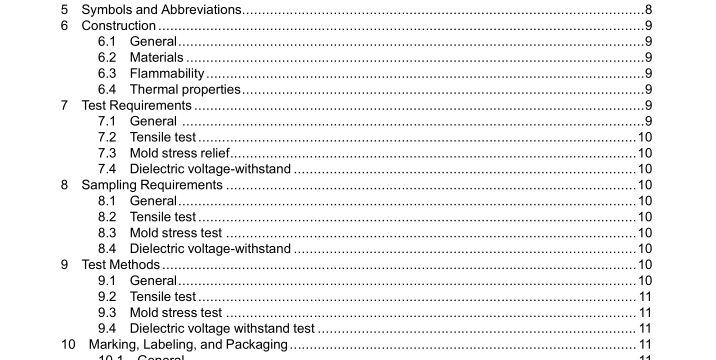

6 Construction 6.1 General 6.1.1 A ferrule shall be provided with one opening to accept one or two stranded type copper conductors applied with compression tooling. 6.1.2 A ferrule shall comply with the dimensional requirements in Table 1 – Table 8 and Figure 1 – Figure 10 and the following: a) Dimensions for the length of the ferrules in all Tables and Figures represent common sizes and longer lengths are permissible as these dimensions are indicated as minimum values. For Table 3 and Table 5, which specify “strip length”, any increase in overall length of the ferrule shall include an equal amount of increase in the strip length specified by the manufacturer. b) Dimensions for the diameter and thickness for plastic sleeves in Table 6 and Table 7 and Figure 8 and Figure 10 represent common sizes. Wider dimensions and thicker materials for the plastic sleeves are permissible, as these dimensions are indicated as minimum values. 6.2 Materials 6.2.1 A ferrule shall be of copper or a copper alloy containing at least 80% copper and be coated with tin. 6.3 Flammability 6.3.1 The covering material shall comply with one of the following requirements for flammability: a) have a minimum flammability classification of HB as determined by tests described in UL 94 or CAN/CSA-C22.2 No. 0.17. This flammability classification may be determined at the minimum thickness employed in the construction or a nominal thickness of 0.8 mm (0.031 in), whichever is greater; b) meet the glow wire test as specified in UL 746C or CSA C22.2 No 0.17 for a temperature of 650° C; or c) be evaluated and classed with a flammability rating of SC-0, SC-1, SC-TC 0, or SC-TC 1 in accordance with UL 1694.UL 486F-2019 pdf download.

UL 486F-2019 pdf download