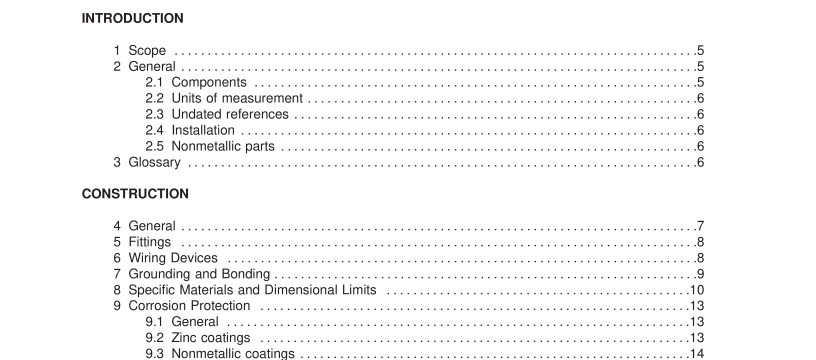

UL 5-2009 pdf download.Surface Metal Raceways and Fittings.

4 General 4.1 A raceway system shall be constructed to facilitate compliance with the requirements for the installation of insulated wires and cables as given in the National Electrical Code, NFPA 70. 4.2 Each element of a raceway system shall comply with the requirements for the construction, performance, and use of that element. 4.3 A raceway shall consist of one or more pieces formed and constructed to make the raceway readily distinguishable from electrical conduit, electrical metallic tubing, electrical nonmetallic tubing, and other raceway systems. 4.4 A raceway system shall provide a complete enclosure that protects the wires installed therein against damage. The complete system, when installed as intended, shall comply with the following: a) There shall not be any openings that exceed 1 /1 6 inch (1 .59 mm) in width on surfaces that are accessible following installation of the system. b) A knockout or break-away tab shall completely cover the opening in which it is located, and the clearance between the knockout or break-away tab and the opening shall not be more than 0.030 inch (0.76 mm). c) Mounting holes having a maximum diameter of 9/32 inch (7.1 mm), or slotted openings for mounting of one dimension not larger than 5/8 inch (1 5.9 mm) and the other dimension not larger than 1 /8 inch (3.2 mm), provided on the raceway base or fitting base surface that is installed flush with the mounting surface, are not prohibited. d) A partition in a raceway system shall not have any openings through which wires are capable of being passed, intentionally or otherwise, from one compartment to another. Exception: A gap of 1 /8 inch (3.2 mm) shall be used only when means is provided to completely contain conductors in their individual compartments, such as wire retaining clips.

4.9 An adhesive strip, when provided on the raceway, shall serve only as a positioning aid during the installation process. The raceway shall also have provisions for mechanical fastening as required in 4.6 – 4.8. Exception: An adhesive strip provided on a raceway shall be used as the sole means of securement only when the raceway is marked for use with Class 2 circuits only, as defined in Article 725 of the National Electrical Code, NFPA 70. 4.1 0 Provision shall be made for securing the cover to the base of a two-piece raceway at intervals of not more than 4 feet (1 .2 m). A cover shall be held in place by continuous grooves, flanges, or similar constructions only when it is securely fixed in place. See 4.1 2. 4.1 1 For raceways using conductors larger than No. 6 AWG (1 3.30 mm 2 ), the Short Circuit Test, Section 1 7, shall be performed on conductors in the raceway to determine whether the cover is secure. 4.1 2 Raceway or fitting covers shall be constructed such that the use of a tool (such as the prying action of a screwdriver) or two simultaneous deliberate actions are required for their removal for gaining access to internal areas of the raceway after installation. 4.1 3 A partition provided in a raceway or fitting shall be secured in position. The partition shall have the strength required to support the maximum wire fill by weight.

7 Grounding and Bonding 7.1 Electrical continuity shall be provided between all metal parts of the raceway system when the parts are installed in the intended manner. See the Electrical Resistance Test, Section 1 5. 7.2 A supplemental set screw or other acceptable positive means of securement shall be provided for each connection between adjacent metal raceway section and between metal raceway sections and fittings of a metal raceway system. Exception: Other methods of providing electrical continuity are to be used only when in compliance with the requirements in the Fault Current Test, Section 1 6. 7.3 A raceway system shall be provided with means for grounding at all points or with fittings intended for connection to another wiring system. 7.4 A metal raceway base or fitting intended for connection to a wiring system shall have a tapped hole adjacent to the wire entry point intended for use with a No. 1 0-32 or larger grounding screw. At least two full threads shall be provided in metal into which screws are to be threaded. Exception: A metal raceway base or fitting is not required to have a tapped hole when it is provided with a fastening means such as a wire attached by a connector, clip, or other means that has been evaluated and determined to be suitable. A self-threading or factory-assembled screw shall be provided instead of a tapped hole only when it is identified for the purpose of securing the grounding conductor. A fastening means is not required when fastening methods are referenced in the instructions.UL 5-2009 pdf download.

UL 5-2009 pdf download