UL 510-2020 pdf download.Polyvinyl Chloride, Polyethylene, and Rubber Insulating Tape.

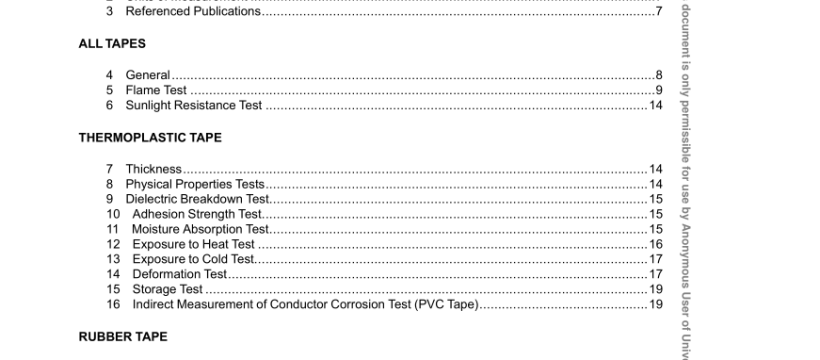

1 Scope 1.1 In the US, this standard covers the following: a) Thermoplastic and rubber tapes for use as electrical insulation at not more than 600 Vand at 80° C (176° F) and lower temperatures on joints and splices in wires and cables in accordance with NFPA 70. It is intended that rubber tape on a joint or splice be mechanically protected by a covering such as friction, PE (thermoplastic polyethylene), or PVC (polyvinyl chloride or a copolymer of vinyl chloride and vinyl acetate)tape. Thermoplastic tape is acceptable without the additional mechanical protection. b) The characteristic constituent of the thermoplastic tape covered in this Standard is either PVC (polyvinyl chloride or a copolymer of vinyl chloride and vinyl acetate), or PE (thermoplastic polyethylene). 1.2 In Canada, this standard covers the following: a) Thermoplastic and rubber tapes for use as electrical insulation at not more than 600 V and 80°C (176°F) and lower temperatures on joints and splices in wire and cables in accordance with the CSA C22.1. It is intended that rubber tape on a joint or splice be mechanically protected by a covering such as friction, PE (thermoplastic polyethylene), or PVC (polyvinyl chloride or a copolymer of vinyl chloride and vinyl acetate) tape. Thermoplastic tape is acceptable without the additional mechanical protection. b) The characteristic constituent of the thermoplastic tape covered in this Standard is PE (thermoplastic polyethylene). Requirements for PVC tape are covered by CSA C22.2 No. 197. 2 Units of Measurement 2.1 Values stated without parentheses are the requirement. Values in parentheses are explanatory or approximate information. 3 Referenced Publications 3.1 Any undated reference appearing in the requirements of this standard shall be interpreted as referring to the latest edition of the reference, including all revisions and amendments. 3.2 The following standards are referenced in this standard, and portions of these referenced standards may be essential for compliance.

4.3 Unless otherwise specified, all testing, except flammability, shall be conducted at 23 ±5°C (73 ±9°F) and a relative humidity of 50 ±10%. Flammability testing shall be conducted in still air at a temperature of 15 – 35°C (59 – 95°F) and a relative humidity of < 75%. All samples shall be preconditioned at 23 ±5°C (73 ±9°F) and a relative humidity of 50 ±10% for a minimum of 30 minutes prior to test, or referred to as the As-Received condition. 4.4 Unless otherwise indicated for a specific test, testing of each construction in the unpigmented and heaviest pigmented dark and light tapes (such as black and white) are considered to represent the range of colors for each test. If the tape is produced with the pigment in different layers, such as the backing, reinforcement and/or adhesive, each of those unique constructions will also require the applicable tests described within this standard. 4.5 Each tape shall be considered a unique construction if the thickness of any individual layer varies by more than 10%. 4.6 Unless otherwise specified in the individual test method, the average of the results for the specimens tested shall be used to determine compliance with the requirements of this standard. 4.7 Unless otherwise specified in the individual test method, tensile strength and elongation results for specimens that break at some obvious flaw or that do not break between the predetermined bench marks shall be discarded. 5 Flame Test 5.1 Insulating tape marked “Flame Retardant” in accordance with 23.2 shall not flame longer than 60 seconds following any of five 15 seconds applications of the test flame, the period between applications being: a) 15 seconds if the specimen flaming ceases within 15 seconds; or b) The duration of the specimen flaming if the specimen flaming persists longer than 15 seconds. 5.2 The tape shall not ignite combustible materials in its vicinity or damage more than 25% of the indicator flag during, between, or after the five applications of the test flame. UL 510-2020 pdf download.

UL 510-2020 pdf download