UL 567-2021 pdf download.Emergency Breakaway Fittings, Swivel Connectors and Pipe-Connection Fittings for Petroleum Products and LP- Gas.

5 Glossary 5.1 For the purposes of this standard the following definitions apply: 5.2 ASTM IRM 903 / IRM 903 – High-swelling petroleum base oil described in ASTM D471, Standard Test Method for Rubber Property – Effect of Liquids. 5.3 ASTM REFERENCE FUEL A – 100 % Isooctane 5.4 ASTM REFERENCE FUEL C – A mixture of 50 % Isooctane + 50 % Toluene by volume. 5.5 ASTM REFERENCE FUEL H – A mixture of 85 % ASTM Reference Fuel C + 15 % Anhydrous Denatured Ethanol by volume. 5.6 AUTHORITY HAVING JURISDICTION (AHJ) – The governmental body responsible for the enforcement of any part of this Standard or the official or agency designated by that body to exercise such a function. 5.7 FITTINGS: a) PIPE-CONNECTING FITTING – A fitting of the threadless compression seal-ring type for use in the assembly of petroleum product dispensing devices to facilitate connection of piping or tubing. These include straight coupling style, tee, ell, reducer, adapter, and other styles. b) RECONNECTABLE FITTING – An emergency breakaway fitting designed such that upon separation it is intended to be reconnected and reused when it is not damaged. c) SINGLE-BREAK FITTING – An emergency breakaway fitting that, upon separation, is not intended to be reconnected and reused.

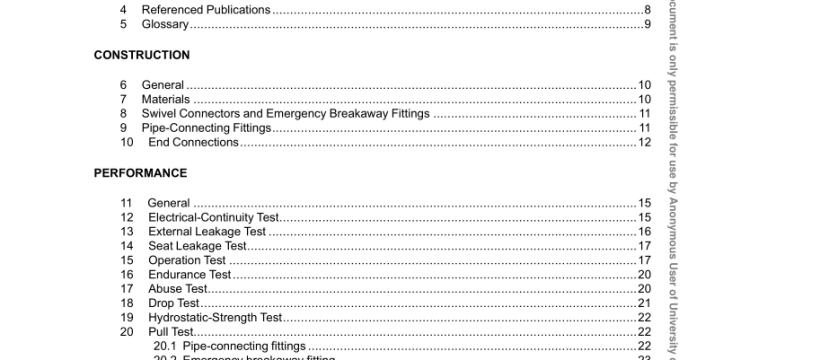

6 General 6.1 A connector or fitting for use with petroleum products shall be constructed for an operating pressure of not less than 50 psig (340 kPa) for the fluid confining portion of the device and 0.5 psig (3.45 kPa) for the vapor confining portion of the device, when provided, and an ultimate rupture pressure of not less than five times the design pressure. 6.2 A swivel connector or emergency breakaway fitting for use with anhydrous ammonia or LP-Gas shall be designed for an operating pressure of not less than 350 psig (2413 kPa) and an ultimate rupture pressure of not less than five times the design pressure. 6.3 An emergency breakaway fitting shall be constructed to separate in the event that the coupling is subjected to a pull force not less than 100 lbf (445 N), and not to exceed 350 lbf (1557 N) for petroleum product service and 400 lbf (1779 N) for anhydrous ammonia or LP-Gas Service. 6.4 A hose assembly provided with an integral swivel connector for petroleum product service shall comply with the applicable requirements in the Standard for Hose and Hose Assemblies for Dispensing Flammable and Combustible Liquids, UL 330. 7 Materials 7.1 Materials in contact with the fluid to be handled shall be inherently resistant to being adversely affected by such fluid. 7.2 A synthetic rubber part shall not show any signs of cracking or other damage following exposure to – 40°F (– 40°C). See the Low Temperature Test, Section 22.

7.7 Cadmium plating shall have a thickness of not less than 0.0003 in (0.0076 mm) and zinc plating shall have a thickness of not less than 0.0005 in (0.013 mm), except on parts where threads constitute the major portion of the area, in which case the thickness of the cadmium or the zinc plating shall not be less than 0.00015 in (0.0038 mm). 7.8 Ammonia containing minute quantities of water reacts rapidly with cadmium, copper, zinc, and many alloys, especially those of copper base. Only iron, steel, and certain nonferrous alloys, determined to be satisfactory for ammonia service, shall be used in contact with anhydrous ammonia. 8 Swivel Connectors and Emergency Breakaway Fittings 8.1 A swivel connector or emergency breakaway fitting for use with petroleum products shall provide electrical continuity from end-to-end across the one or more swivel joints, when provided, so that when the connector is installed, continuity is provided for grounding of static charges. Such continuity shall be inherent in the construction and shall not be accomplished by a jumper wire. 9 Pipe-Connecting Fittings 9.1 A seal ring of a fitting shall not be exposed to physical damage when the sealing nut is tightened. 9.2 A fitting shall provide electrical continuity across the fitting for grounding of static charges. Such continuity shall be inherent in the construction and shall not be accomplished by a jumper wire. 9.3 A fitting for the connection of pipe or tubing shall be made to provide strength at least equal to that of a fitting constructed from one of the materials indicated in Table 9.1. The wall thickness shall not be less than that specified under the appropriate column.UL 567-2021 pdf download.

UL 567-2021 pdf download