UL 852-2008 pdf download.Metallic Sprinkler Pipe for Fire Protection Service.

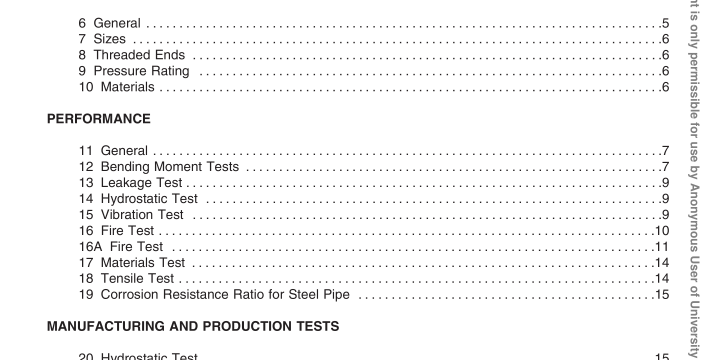

7 Sizes 7.1 Pipe shall be nominal 1/2-inch NPS or larger. 8 Threaded Ends 8.1 Where steel pipe is intended to be threaded, threads shall comply with the Standard for Pipe Threads, General Purpose (Inch), ANSI/ASME B1.20.1. Exception: Steel pipe intended for use in installations where fittings incorporate pipe threads other than NPT type threads, shall be permitted to be provided with pipe threads complying with other nationally or internationally recognized pipe thread standard compatible with those fittings. 9 Pressure Rating 9.1 Pipe shall be constructed for a minimum rated pressure of 175 psig (1206 kPa). 10 Materials 10.1 The pipe shall comply with the dimensional, chemical, and physical properties of the applicable ASTM Standards or other nationally or internationally recognized pipe standards. Exception: If the pipe is produced to specifications beyond the scope of ASTM Standards, or other nationally or internationally recognized standards, the pipe shall conform to specifications established by the manufacturer. 10.2 Steel pipe shall be made of steel material having corrosion resistance properties at least equivalent to Schedule 40 black steel pipe made in accordance with Standard Specification for Black and Hot-Dipped Zinc-Coated (Galvanized) Welded and Seamless Steel Pipe for Fire Protection Use, ASTM A795, or Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless, ASTM A53 or or Standard Specification for Electric-Resistance-Welded Steel Pipe, ASTM A 135/A 135M.

11 General 11.1 To determine compliance with these requirements, pipe shall be subjected to the performance tests described in Sections 12 – 18, and specified in Table 12.1. 11.2 The number of samples required for investigation varies due to pipe sizes, material, and application. The number of samples required for examination and test are to be determined following a review of detailed drawings, examination of a preliminary sample, or both. 12 Bending Moment Tests 12.1 Sample pipe and joint assembly shall not leak or rupture when subjected to the specified bending moment. During the tests, the assembly is to be pressurized to the rated pressure. 12.2 Sample pipe in each size is to be assembled with a joint representative of the intended application at the center of two lengths of pipe each measuring at least 12 inches (305 mm).

16A Fire Test 16A.1 Steel pipe having thickness less than Schedule 5 in accordance with Standard Specification for Black and Hot-Dipped Zinc-Coated (Galvanized) Welded and Seamless Steel Pipe for Fire Protection Use, ASTM A795, Standard Specification for Electric Resistance Welded Steel Pipe, ASTM A1 35, or Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless, ASTM A53, or equivalent, or pipe fabricated of material other than steel, shall withstand the fire exposure specified in 16A.2 – 16A.13 without leakage of the piping material or rupture of the joints or piping material when subjected to the indicated flowing pressures and a post fire exposure hydrostatic test at the rated pressure. 16A.2 For a product type with a size range of analogous design, the smallest diameter pipe and 2 inch size pipe shall be tested. If the entire size range is greater than nominal 2 inch, only the smallest diameter pipe shall be tested. If the entire size range is less than nominal 2 inch, the smallest diameter pipe and largest diameter pipe shall be tested. 1 6A.3 The fire source is to consist of a line-burner assembly with four spray nozzles arranged to discharge heptane at a nominal flow rate of 1.6 gpm (6.0 l/min) for stage 1 resulting in a fire having a nominal total heat release rate of 3,000 kW. The line-burner assembly shall also be capable of a heptane nominal flow rate of 0.5 gpm for stage 2. The spray nozzles are to be spaced 24 inches (610 mm) apart on the supply line and 24 inches (610 mm) above the floor. UL 852-2008 pdf download.

UL 852-2008 pdf download