UL 536-2021 pdf download.Flexible Metallic Hose.

1.9 This standard does not cover the following: a) Gas appliance hose connectors for handling fuel gases at 5 psig (34.5 kPa) or less, which is covered by Connectors for Gas Appliances, CSA 6.10/ANSI Z21.24; b) Portable outdoor cooking appliance fuel hose, which is covered by Gas Hose Connectors for Portable Outdoor Gas-Fired Appliances, CSA 8.4/ANSI Z21.54; c) LP-Gas and natural gas delivery hose or fuel supply systems, which is covered by the Standard for Pigtails and Flexible Hose Connectors for LP-Gas, UL 569 and the Standard for LP-Gas Hose, UL 21 or the Standard for Elastomeric composite hose and hose couplings for conducting propane and natural gas, CSA 8.1, and the Standard for Thermoplastic hose and hose couplings for conducting propane and natural gas, CSA 8.3; d) Underground piping products for liquid fuels, which is covered by the Outline of Investigation for Metallic Underground Fuel Pipe, UL 971A, or the Standard for Metallic and Nonmetallic Underground Piping for Flammable and Combustible Liquids, CAN/ULC-S679; e) Flexible connector piping for liquid fuels, which is covered by the Standard for Flexible Connector Piping for Fuels, UL 2039, or the Standard for Flexible Connector Piping for Fuels, CAN/ULC-S633; f) Motor fuel dispensing hose, which is covered by the Standard for Hose and Hose Assemblies for Dispensing Flammable and Combustible Liquids, ANSI/CAN/UL 330. 2 Components 2.1 Except as indicated in 2.2, a component of a product covered by this standard shall comply with the requirements for that component. 2.2 A component is not required to comply with a specific requirement that: a) Involves a feature or characteristic not required in the application of the component in the product covered by this standard, or b) Is superseded by a requirement in this standard.

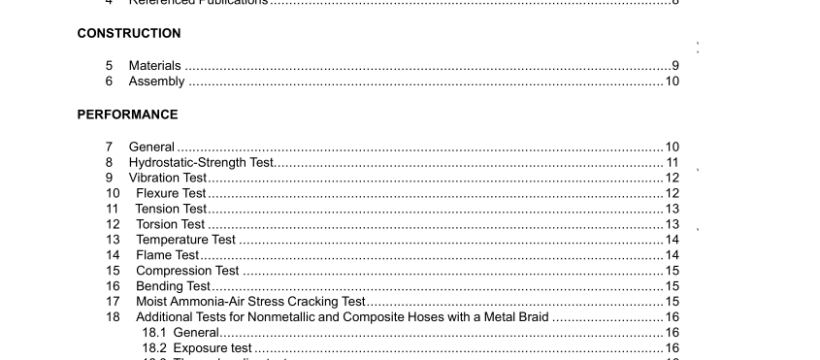

7.3 If flexible metallic hose is made in larger than 4 in (101.6 mm) diameters, the 4 in (101.6 mm) diameters are considered to be representative of the larger diameter flexible metallic hose. 7.4 If samples are specified for tests involving bending of the sample, the length of sample is to be such that the hose may be bent over an arc of at least 45° with the radius of curvature designated for the test. If samples are specified to be the shortest, they are to be prepared using the minimum length to be designated by the manufacturer as indicated in 7.1(b) or the shortest length the test equipment is capable of testing, whichever is longer. 7.5 Tests are shall be conducted in the order in which they are presented, using new samples for each test. If a manufacturer desires to reduce the number of samples, tests such as the Temperature Test, Section 13, and Flame Test, Section 14, may be conducted using samples previously subjected to other tests, such as the Hydrostatic Strength Test, Section 8. 7.6 Water or other nonhazardous liquid is not prohibited from being used for developing the required pressure in a hydrostatic pressure strength test. 8 Hydrostatic-Strength Test 8.1 A flexible metallic hose assembly of length sufficient to make a 90° bend based on the radius of curvature as specified in 7.2 is to be used in this test. The hose shall not leak nor rupture when subjected for at least 1 min to a hydrostatic pressure equivalent to five times its maximum rated pressure. 8.2 One sample of each diameter is to be used in this test. The sample is to be installed in a straight line, with one end attached to the pressure source and other end plugged and free.

9 Vibration Test 9.1 Flexible metallic hose shall not leak or show evidence of damage when subjected to vibration as specified in 9.3 while pressurized as specified in 9.4 and 9.5 and subjected to vibration of an amplitude of 0.075 in (1.91 mm) and a frequency of 900 to 1000 vibrations per minute for at least 300 h. 9.2 Two samples 16 in (406 mm) long or the shortest manufactured length, of each diameter, are to be used in this test. One sample of each diameter is to be installed in a vibration machine in a straight line. The other sample of each diameter is to be similarly installed, except that it is to be bent with a radius of curvature as specified in 7.2. 9.3 The vibration machine is to provide means for applying hydrostatic pressure to any one end of the sample, and that end is to be mounted so as to be stationary. The opposite end of the sample is to be plugged and subjected to a motion in one plane. The motion is to have a displacement of 0.15 in (3.81 mm). 9.4 The maximum rated pressure is to be maintained in the sample during the period of vibration. 9.5 The sample is to be subjected to vibration for at least 300 h, after which the hydrostatic pressure is to be increased to 1-1/2 times maximum rated pressure and then immediately released.UL 536-2021 pdf download.

UL 536-2021 pdf download