UL 2367-2021 pdf download.Solid State Overcurrent Protectors.

1.2 The devices covered by these requirements are integrated circuits, and electrical spacings within the devices are not specified. 1.3 The devices covered by these requirements are entirely electronic in nature and have no means for mechanical operation or reset. 1.4 The terminals of the devices covered by these requirements are for factory wiring only (intended to be mounted on a printed wiring board). 1.5 This Standard also covers devices intended to be used as limited power source current limiters in accordance with UL 62368-1, Audio/Video, Information and Communication Technology Equipment – Part 1: Safety Requirements, and UL 60950-1, Information Technology Equipment – Safety – Part 1: General Requirements. These devices limit output currents to values less than the protective current rating of 5 amperes and a maximum output power of 100 VA. 1.6 The devices covered by these requirements limit output currents to values less than the overcurrent protection rating of 5 amperes. 1.7 The devices covered by these requirements have only been evaluated for supplementary overcurrent protection of secondary circuits supplied by the load side of a transformer, power supply or battery and have not been evaluated for branch-circuit protection. 1.8 This Standard may cover devices intended for use in telecommunications applications. However, devices intended for connection to telecommunications networks with outside plant connections should be evaluated in the end-use in accordance with the requirements of the Standard for Information Technology Equipment – Safety – Part 1: General Requirements, UL 60950-1, the Standard for Audio/Video, Information and Communication Technology Equipment – Part 1: Safety Requirements, UL 62368-1, or the Standard for Secondary Protectors for Communication Circuits, UL 497A, as appropriate. 1.9 This Standard also covers solid-state overcurrent protectors that are identified as providing Class 2 limitations as defined in the National Electrical Code, NFPA 70. See Section 10, Class 2 Limitations per NFPA 70, Article 725.

5.3 ENCAPSULANT – A molding material that is typically cast or injection molded around and is intended to insulate and protect the device. Encapsulated devices do not employ supplementary surrounding shells hence the encapsulant functions as an electrical enclosure. 5.4 EXPOSED PLANT (OUTSIDE PLANT) – Any portion of the telecommunications network subject to accidental contact with or induction from power conductors at a voltage exceeding 300V to ground. This includes circuitry that is intended to be connected to the Public Switched Telephone Network (PST-N), Off- Premises Extension (OPE) lines, and the like. 5.5 MAXIMUM CONTINUOUS CURRENT (CONT. CURRENT) – This designation is the ampere rating for which a protector or family of protectors has been tested for continuous current operation. 5.6 OPERATING AMBIENT TEMPERATURE RANGE – The ambient temperature range for the protector when operating in accordance with the manufacturer’s specifications. 5.7 PROTECTIVE CURRENT (PROT. CURRENT) – This designation is the ampere rating for which a protector or family of protectors has been tested for providing overcurrent protection. 5.8 TELECOMMUNICATION (TELEPHONE) NETWORK CIRCUIT – An electrical circuit conductively connected to the telephone company communications facilities. 5.9 TELECOMMUNICATION NETWORK CONNECTIONS (TNC) – Identified as follows: a) Not intended for use on telecommunication network with outside plant connections. b) Intended for use on telecommunication network with outside plant connections. 5.10 VOLTAGE RANGE (VOLTS) – This designation is the voltage range for which a protector or family of protectors has been tested. Unless specified otherwise, all voltages are direct current (DC).

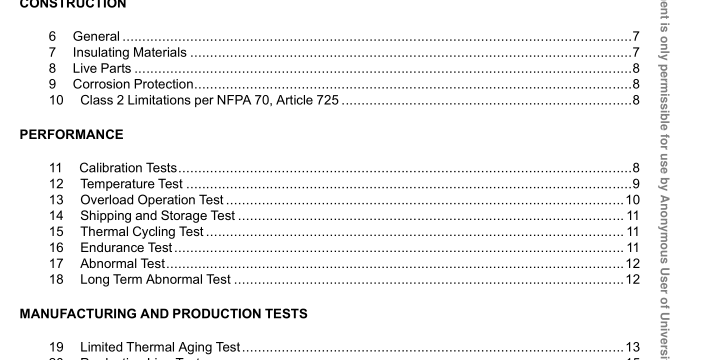

6 General 6.1 A solid-state overcurrent protector shall be constructed in compliance with Sections 7 – 10. 7 Insulating Materials 7.1 Uninsulated live parts involving risk of fire, electric shock, or electrical-energy/high-current levels shall be mounted on porcelain, phenolic-composition, or other material that is intended for the application. 7.2 Thermoplastic materials used for the direct or indirect support of uninsulated live parts involving a risk of fire, electric shock, or electrical-energy/high-current shall comply with the requirements in UL 746C. 7.3 Molded parts shall have the mechanical strength and rigidity to withstand the stresses of actual service. 7.4 Materials used as encapsulants shall operate within their RTI as specified in UL 746B or alternatively shall comply with the Limited Thermal Aging Test, Section 19.UL 2367-2021 pdf download.

UL 2367-2021 pdf download