UL 1077-2009 pdf download.Supplementary Protectors for Use in Electrical Equipment.

2.1 1 TRIP CURRENT – The current at which an overcurrent-trip protector is intended to open the contact circuit at a given ambient temperature and a given time. 2.1 2 TRIP-FREE – A protector designed so that the contacts cannot be held in the closed position by the operating means during trip command conditions. 2.1 2 effective July 1 4, 2008 2.1 3 TRIP-FREE, CYCLING – A protector designed so that the contacts cannot be held in the closed position by the operating means during trip command conditions, but will reclose when the closing command is maintained. The protector will continue to close momentarily and repeatedly as long as the close command is maintained by the operating means during trip command conditions. 2.1 3 effective July 1 4, 2008 2.1 4 TRIP MECHANISM – The part of the protector that senses the abnormal condition in the circuit and causes the contact circuit to open. 2.1 5 TRIP VOLTAGE – The voltage at which an overvoltage protector or undervoltage protector is intended to trip. 2.1 6 UNDERVOLTAGE-TRIP PROTECTOR – A magnetic trip protector intended to trip the contact circuit when the voltage across the trip coil falls below a predetermined value. 3 Components 3.1 Except as indicated in 3.2, a component of a product covered by this Standard shall comply with the requirements for that component. See Appendix A for a list of standards covering components generally used in the products covered by this Standard. 3.2 A component is not required to comply with a specific requirement that: a) Involves a feature or characteristic not required in the application of the component in the product covered by this standard, or b) Is superseded by a requirement in this standard. 3.3 A component shall be used in accordance with its rating established for the intended conditions of use.

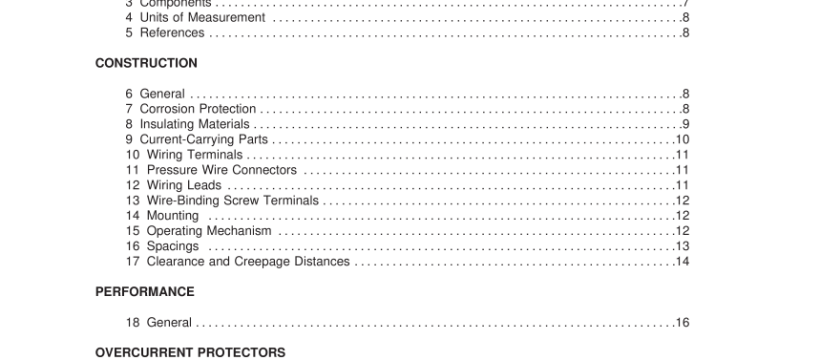

4 Units of Measurement 4.1 Values stated without parentheses are the requirement. Values in parentheses are explanatory or approximate information. 5 References 5.1 Any undated reference to a code or standard appearing in the requirements of this standard shall be interpreted as referring to the latest edition of that code or standard. CONSTRUCTION 6 General 6.1 A protector shall have an integral housing for all mechanisms and live parts, except the operating handle and the wiring terminals, and shall be capable of being operated or reset without opening the housing. 6.2 A protector shall be so formed and assembled that it shall have the strength and rigidity necessary to resist the ordinary abuses to which it is capable of being subjected (including the tests specified in this Standard), without increasing its risk of fire, shock or personal injury due to partial or total collapse with a resulting reduction of spacings, loosening or displacement of parts, or other serious defect. 7 Corrosion Protection 7.1 Iron and steel parts except for thermal elements, magnet pole faces, hardened and polished parts such as latching surfaces, and other similar parts, where such protection is impractical, shall be acceptably protected against corrosion by enameling, galvanizing, plating, or other equivalent means. 7.2 The requirements of 7.1 apply to all housings and to all springs and other parts upon which proper mechanical operation depends. It does not apply to small minor parts of iron or steel such as washers, screws, bolts, and other similar parts that are not current-carrying, or to other parts where the malfunction of such unprotected parts would not be likely to result in a risk of fire, electric shock or personal injury. Parts made of stainless steel, properly polished or treated when necessary, do not require additional protection against corrosion.

8 Insulating Materials 8.1 Insulating material for the support of current-carrying parts shall be strong, not easily ignited, and moisture resistant. A material other than porcelain, phenolic, or one that has not been evaluated for the support of current-carrying parts shall be investigated under conditions of actual service to determine if it has the necessary electrical, mechanical, and flammability properties and otherwise meets the intent of the requirements for the particular application. The properties of the material shall be such that it shall withstand the most severe conditions likely to be met in service.UL 1077 pdf download.

UL 1077-2009 pdf download