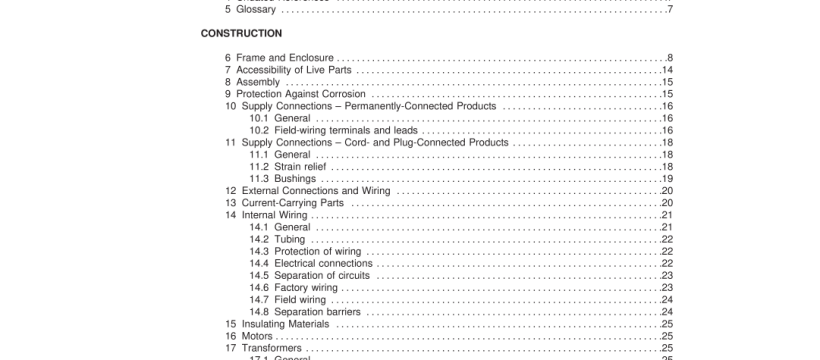

UL 1564-2009 pdf download.Industrial Battery Chargers.

3 Units of Measurement 3.1 Values stated without parentheses are the requirement. Values in parentheses are explanatory or approximate information. 4 Undated References 4.1 Any undated reference to a code or standard appearing in the requirements of this standard shall be interpreted as referring to the latest edition of that code or standard. 5 Glossary 5.1 In the following text, the term ″product″ is used to mean an industrial battery charger. 5.2 For the purpose of this standard, the following definitions apply. 5.3 CLASS 2 TRANSFORMER – A step-down transformer complying with the applicable requirements in the Standard for Low Voltage Transformers – Part 1 : General Requirements, UL 5085-1 and the Standard for Low Voltage Transformers – Part 3: Class 2 and Class 3 Transformers, UL 5085-3, or the Standard for Class 2 Power Units, UL 1 31 0. 5.3 revised November 1 2, 2008 5.4 INDUSTRIAL BATTERY – A battery that is intended for cycling service and is rated in number of cells and in ampere-hours delivered at the 6-hour discharge rate. 5.5 LIMITED-ENERGY CIRCUIT – An ac or dc circuit having a voltage not exceeding 1 000 volts and the energy limited to 1 00 volt-amperes by either a secondary winding of a transformer, one or more resistors complying with 24.4.1 0 and 24.4.1 1 , or a regulating network complying with 24.4.1 .

6.6 An enclosure consisting of wire mesh, perforated screens, or grillwork shall be provided with a rigid supporting frame such that the deformation of a guard or enclosure does not result in contact with live parts. 6.7 The diameter of the wires of a screen shall not be less than 0.0598 inch (1 .51 9 mm) if the screen openings are 1 /2 square inch (3.2 cm 2 ) or less in area and shall not be less than 0.1 00 inch (2.54 mm) for larger screen openings. 6.8 Perforated sheet steel and sheet steel used for expanded metal mesh shall not be less than 0.042 inch (1 .07 mm) thick, 0.058 inch (1 .47 mm) thick if nonferrous, if the mesh openings or perforations are 1 /2 square inch (3.2 cm 2 ) or less in area, and shall not be less than 0.080 inch (2.03 mm) thick, 0.1 1 2 inch (284 mm) thick if non-ferrous, for larger openings. Exception: In a small charger where the indentation of a guard or enclosure does not affect the clearance between uninsulated, movable, current-carrying parts and grounded metal, 0.020 inch (0.51 mm) steel or 0.029 inch (0.74 mm) nonferrous expanded metal mesh may be employed, provided that: a) The exposed mesh on any one side or surface of the battery charger that is so protected has an area of 72 square inches (465 cm 2 ) or less and does not have any dimension greater than 1 2 inches (305 mm); or b) The width of the protected opening is 3-1 /2 inches (88.9 mm) or less. 6.9 If an electrical instrument, such as a meter, forms part of the enclosure, the face or the back of the instrument housing, or both together, shall comply with the requirements for an enclosure. Exception No. 1 : This requirement does not apply to an electrical instrument connected in a secondary circuit where damage to or deterioration of the materials of which the housing is made does not result in a risk of fire or electric shock.

6.1 1 Supporting feet of a product that form part of the enclosure or are needed for ventilation shall be reliably secured and the aging, physical, and flammability properties of the material shall be investigated. The effect of oil and the absorption of moisture on the mounting feet are also to be considered. Exception: Supporting feet may be accepted without testing if they do not form part of the enclosure and are not needed to provide ventilation. 6.1 2 An enclosure, frame, or cover of a material other than sheet metal shall provide protection equivalent to that required by 6.4. 6.1 3 Among the factors taken into consideration when judging the acceptability of a nonmetallic enclosure are: a) Mechanical strength; b) Resistance to impact; c) Moisture-absorptive properties; d) Combustibility; e) Resistance to distortion at temperatures to which the material may be subjected under conditions of normal or abnormal usage; and f) Resistance to arcing. The enclosure material shall not display a loss of a property beyond the minimum acceptable level as a result of aging. See the Standard for Polymeric Materials – Use in Electrical Equipment Evaluations, UL 746C. 6.1 4 The combination of enclosure and internal barriers of a product shall prevent molten metal, burning insulation, flaming particles, or the like, from falling onto combustible materials, including the surface upon which the charger is supported. See Figure 6.1 . An internal barrier may be an integral part of a component or of the charger enclosure. Compliance shall be determined in accordance with 6.1 5 and 6.1 6.UL 1564-2009 pdf download.

UL 1564-2009 pdf download