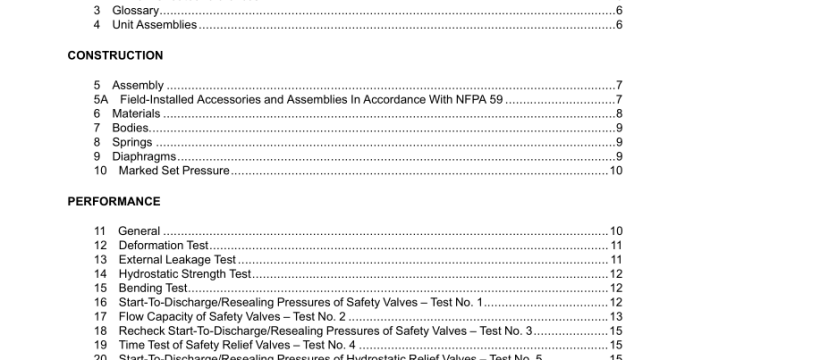

UL 132 2020 pdf download.Safety Relief Valves for Anhydrous Ammonia and LP-Gas.

6 Materials 6.1 An operating or fluid-confining part of a valve shall have the strength and durability to provide reliable service of the part and of the assembly, when failure of the part is capable of allowing leakage or risk of fire or injury. 6.2 A part in contact with the fluid to be handled shall be resistant to the action of such fluid. Ammonia containing minute quantities of water reacts rapidly with copper, zinc, and many alloys, especially those of copper base. 6.3 A part used for a body or closure shall have a melting point of no less than 1500°F (816°C), a tensile strength of no less than 30,000 psi (206.7 MPa), and an elongation of no less than 10 percent in 2 inches (50.8 mm). Exception: An alloy equivalent to Specification 6061–T6 for aluminum, in accordance with the Alloy and Temper Designation Systems for Aluminum, ANSI H35.1/H35.1M, is not prohibited from being used for anhydrous ammonia valves. 6.4 Nonductile cast iron (regular gray iron) shall not be used for a body or closure in contact with anhydrous ammonia and LP-Gas. Malleable iron, ductile iron, and cast steel conforming with or exceeding the specifications for such materials as specified in the following standards, respectively, are not prohibited from being used for anhydrous ammonia and LP-Gas valves: a) Standard Specification for Ferritic Malleable Iron Castings, ASTM A47/A47M-99 (2014); b) Standard Specification for Ferritic Ductile Iron Pressure-Retaining Castings for Use at Elevated Temperatures, ASTM A395/A395M-99 (2014); and c) Standard Specification for Steel Castings, Carbon, for General Application, ASTM A27/A27M- 13. 6.5 When corrosion of a ferrous part interferes with the intended function of a valve, the part shall be provided with a corrosion-resistant protective coating.

7 Bodies 7.1 A threaded section of a body intended for mounting the valve in position or for connection of pipe shall have a wall thickness no less than that of threaded Schedule 80 pipe of corresponding size. The body shall provide means for the application of tools and have the strength to withstand the stresses imposed in effecting a tight joint. 7.2 Pipe threads shall be in accordance with the Standard for Pipe Threads, General Purpose (Inch), ASME B1.20.1. Exception: Valves intended for use in installations where pipe fittings incorporate other than NPT type threads shall be permitted to be provided with pipe threads complying with a national pipe thread standard compatible with those fittings. The pipe thread type shall be identified in accordance with 28.6. 7.3 A flange or a flange-type valve shall conform to the appropriate American National Standard for Pipe Flanges and Flange Fittings covering the material from which the flange is made. 7.4 A valve intended for use with a vent extension or a discharge pipe shall be threaded or otherwise constructed to permit connection of such an extension or pipe. 7.5 When the construction of a safety valve for LP-Gas is such that the valve is capable of retaining water on the discharge side of the seat, the body shall be provided with a drain at the lowest point where water collects. Exception: An LP-Gas safety valve of the internal or recessed design for use only with a motor-fuel containerorcargo tankis not required to be provided with a drain at the lowest part, forwaterdrainage. 7.6 A functional body part shall be prevented from loosening as the result of the turning effort exerted by mounting or dismounting the valve, or by connecting or disconnecting pipe. 7.7 A plug, cap, bonnet, or other part threaded into or on a valve body shall engage no fewer than four full threads. Exception: An adapter or other part intended for connection of a vent extension may engage fewer than fourfull threads. UL 132 2020 pdf download.

UL 132-2020 pdf download