UL 360 2020 pdf download.Liquid-Tight Flexible Metal Conduit.

1 Scope 1.1 These requirements cover the 3/8 (12), 1/2 (16), 3/4 (21), 1 (27), 1-1/4 (35), 1-1/2 (41), 2 (53), 2-1/2 (63), 3 (78), 3–1/2 (91), and 4 (103) trade sizes (metric designators) of liquid-tight flexible steel, aluminum, brass, bronze, copper, and stainless steel conduit. The conduit covered is intended for installation in accordance with the National Electrical Code (NFPA 70) as raceway for wires and cables. 1.2 This conduit is for applications in which flexibility of the conduit is necessary during installation, operation, or maintenance and the contained conductors need protection from vapors, liquids or solids. 1.3 This conduit is circular in cross section, having an outer liquid-tight, nonmetallic, sunlight-resistant jacket over an inner flexible metal core, and is for use in wet, dry, or oily locations in which the conduit is exposed but is not subject to physical damage. Conduit that is not marked with a temperature designation or is marked “60 C” is for use at temperatures not in excess of 60°C (140°F). Conduit that is for use in dry or oily locations at a temperature higher than 60°C (140°F) is marked “____C dry, 60 C wet, 70 C oil res” or “____C dry, 60 C wet, 70 C oil resistant” with “80 C” or “105 C” inserted as the dry-locations temperature. 1.4 Conduit that is marked “80 C dry, 60 C wet, 60 C oil res” or “80 C dry, 60 C wet, 60 C oil resistant” is for use at 80°C (176°F) and lower temperatures in air, and 60 °C (140°F) and lower temperatures where exposed to water, oil or coolants – that is, to cutting oils and the like in machine-tool and other industrial applications. 1.5 Conduit marked in accordance with 24.4(g) is limited to use in oil free environments. 1.6 Fittings for conduit are covered in the Standard for Conduit, Tubing, and Cable Fittings, UL 514B. 1.7 These requirements do not cover liquid-tight flexible nonmetallic conduit.

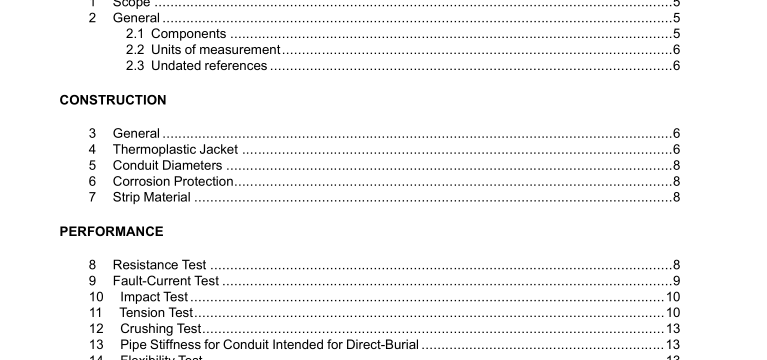

2.2 Units of measurement 2.2.1 Values stated without parentheses are the requirement. Values in parentheses are explanatory or approximate information. 2.3 Undated references 2.3.1 Any undated reference to a code or standard appearing in the requirements of this standard shall be interpreted as referring to the latest edition of that code or standard. CONSTRUCTION 3 General 3.1 Liquid-tight flexible metal conduit shall be fabricated from metal that will provide the mechanical and electrical properties to comply with the performance requirements of this standard. 3.2 Steel conduit in trade sizes 3/8 – 1-1/4 (12 – 35) shall be provided with a bonding strip wound enclosed by the conduit convolutions throughout the entire length of the conduit. Conduit made from aluminum, brass, bronze, copper, and stainless steel in these trade sizes shall be tested according to the Resistance Test, Section 8 and the Fault Current Test, Section 9 to determine the need for a bonding strip. The material and dimensions of the bonding strip shall result in the finished conduit having the resistance values shown in Table 8.1 before high-current testing and shall not adversely affect the flexibility and minimum bending radii of the finished conduit. 3.3 A metallic braiding material with a minimum wire diameter (O.D.) of 0.005 inches (0.13 mm) may be optionally provided between the metal conduit and the outer jacket. When the conduit core material is aluminum, the metallic braiding material, if present, shall be aluminum or tinned metal.

4 Thermoplastic Jacket 4.1 The thickness of the finished jacket shall not be less than indicated in Table 4.1 when determined as described in 4.2. 4.2 The minimum average thickness of the jacket is to be determined by measuring a specimen of the jacket removed from the finished conduit and buffed to remove any ridges or other irregularities on the inside surface of the jacket. The specimen is to be selected to include the thinnest portion of the jacket as determined visually. Measurements are to be made with a dead-weight dial micrometer having a presser foot 0.250 ±0.010 inch (6.4 ±0.2 mm) in diameter and exerting a total of 3.0 ±0.1 ozf (0.84 ±0.02 N or 85 ±3 gf) on the specimen – the load being applied by means of a weight. Five readings are to be taken at different points on the specimen and the average taken as the minimum acceptable average thickness, or by means of an optical device accurate to at least 0.001 inch (0.01 mm).UL 360 2020 pdf download.

UL 360-2020 pdf download