UL 142-2019 pdf download.Steel Aboveground Tanks for Flammable and Combustible Liquids.

3.3 ATMOSPHERIC TANK — A storage tank that has been designed to operate at pressures from – 0.5 psig to 1.0 psig (— 3.4 kPa to 6.9 kPa) measured at the top of the tank.

3.4 DIKE — A single wall construction forming a bottom and sides with open or closed top intended to provide secondary containment of aboveground tank(s) but not intended to be pressurized for leak testing. Dike types include combinations of rectangular or cylindrical shapes or horizontal or vertical orientations. Open top dike constructions do not have covers to prevent precipitation or debris from entering the dike area. Closed top dike constructions have covers to resist precipitation or debris from entering the dike area.

3.5 DIKED TANK — A primary or secondary containment tank within a steel open or closed dike intended to provide at least 110 percent containment capacity of the primary tank(s) and spill containment.

3.6 EMERGENCY VENT — A storage tank opening or device that automatically relieves excessive internal pressure due to an external fire exposure or blockage of the normal vent.

3.7 INTERSTITIAL SPACE (ANNULAR SPACE or INTERSTICE) — A space between the walls of a multiple wall tank that is capable of communicating fluid from a leak in an adjacent wall to a collection point for monitoring.

3.8 NORMAL VENT — A storage tank opening or device that automatically relieves internal pressure or vacuum during normal storage (atmospheric pressure equalization) and during normal operations (fill or withdraw). Normal vents are designed so as not to exceed 1.0 psig (6.9 kPa) pressure and minus 0.5 psig (minus 3.4 kPa) in the tank.

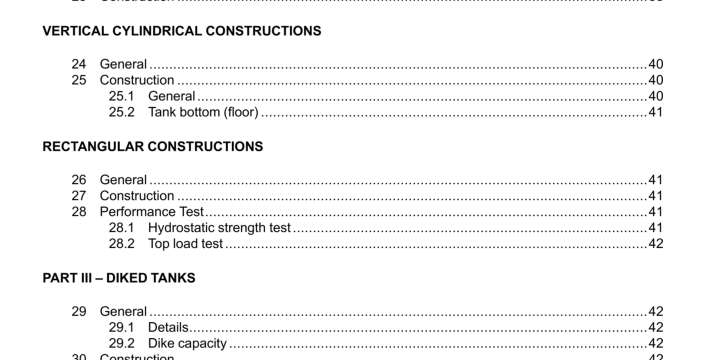

3.9 PERFORMANCE TESTS — A complete evaluation conducted on a limited quantity of representative tanks. These tests are intended to verity compliance with all applicable performance requirements in a standard.

3.10 PRIMARY CONTAINMENT — The ability of a tank design and construction to contain a liquid while in normal use.

3.11 PRIMARY CONTAINMENT TANK — The wall of a tank construction that provides primary containment.

3.12 PRODUCTION TESTS — A limited evaluation conducted on each tank prior to shipping. These tests are intended to verily compliance with production requirements in a standard, such as leakage.

3.13 SECONDARY CONTAINMENT — The ability of a tank design or construction to contain a liquid only in abnormal use (from primary containment leakage or rupture).

3.14 SECONDARY CONTAINMENT ABOVEGROLJND TANK FOR FLAMMABLE LIQUIDS – A primary containment aboveground tank contained within a steel secondary containment shell forming an interstitial (annular) space, which is capable of being monitored for leakage into the space from either the interior or exterior walls. Secondary containment aboveground tank types indude: horizontal cylindrical, vertical cylindrical, and rectangular.

3,15 STORAGE TANK (TANK) — A vessel having a liquid capacity that exceeds 60 gal (230 L), is intended for stationary installation, and is not used for processing.

5.3 Stainless steel shall comply with the Specification for Stainless and Heat Resisting Chromium-Nickel Steel Plate, Sheet, and Strip, ASTM A167; or Specification for Heat-Resisting Chromium and Chromium- Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels, ASTM A240/A240M. 5.4 The thickness of steel is to be determined by five micrometer readings equally spaced along the edge of the full piece as rolled. Thickness is to be determined on the plate or sheet not less than 3/8 inch (9.5 mm) from a cut edge and not less than 3/4 inch (19.1 mm) from a mill edge. 6 Joints 6.1 Joint types for specific tank geometries shall be selected from Table 6.1 and shall comply with the constructions referenced in the appropriate Figures.

8 Venting 8.1 Each tank shall have normal and emergency openings for venting. These vent openings shall be in addition to the fll, withdrawal, and liquid level gauge openings, and shall terminate vertically above the top of the tank. 8.2 Each primary containment tank including each compartment of a compartment tank shall have provisions for both normal venting and emergency venting. The tank penetration openings for these vents shall be located on the top of the tank. Horizontal cylindrical tanks shall center these vents along the top longitudinal axis. 8.3 The interstitial space of a secondary containment tank shall have provisions for emergency venting. The tank penetration opening for this vent shall be located on the tank top, or near the top provided the penetration opening is above the liquid level should the primary tank leak at rated nominal capacity per4.3 (a) into the interstitial space. See Figure 8.1 for one allowable option.UL 142-2019 pdf download.

UL 142-2019 pdf download