UL 1581-2008 pdf download.Reference Standard for Electrical Wires, Cables, and Flexible Cords.

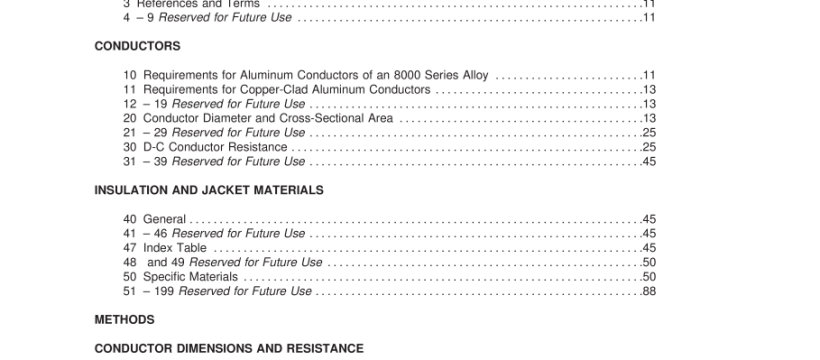

1 Scope 1 .1 This standard contains specific details of the conductors, of the insulation, of the jackets and other coverings, and of the methods of sample preparation, of specimen selection and conditioning, and of measurement and calculation that are required in wire and cable standards. 1 .1 revised July 28, 2008 1 .2 The requirements for the particular materials, construction, performance, and marking of an individual type of wire, cable, or flexible cord are stated in the standard covering the finished type. They are not part of this reference standard. 1 .3 In each case in which an element of this standard does not apply, the standard covering the finished type so states and specifies what does apply. 2 Units of Measurement 2.1 In addition to being stated in the inch/pound units that are customary in the USA, each numerical requirement in this standard is also stated in units that make the requirement conveniently usable in countries employing the metric system. Equivalent– although not exactly identical – results are to be expected from applying a requirement in inch/pound or metric units. Equipment calibrated in metric units is to be used when a requirement is stated in metric terms. 2.1 revised July 28, 2008 3 References and Terms 3.1 The term ″wire standard″ as used in this standard means any standard that covers finished electrical wires, cables, or flexible cords and in which reference is made to this reference standard (UL 1 581 ). 4 – 9 Reserved for Future Use

11 Requirements for Copper-Clad Aluminum Conductors 1 1 .1 The requirements in this section (1 1 .1 ) cover copper-clad aluminum conductors. Copper-clad aluminum conductors shall be drawn from copper-clad aluminum rod. The copper shall be metallurgically bonded to the aluminum core, shall occupy 1 0 percent or more of the cross section of a solid conductor and of each wire (strand) of a stranded conductor, and shall be concentric with the aluminum. The thickness of the copper shall not be less than 2.56 percent of the diameter of the solid conductor or wire (strand) as determined by microscopic examination of a polished right cross section of the round strand or round solid conductor. The tensile strength of a finished copper-clad aluminum conductor tested as a unit or of the wires (strands) from a finished stranded copper-clad aluminum conductor and of a finished solid copper-clad aluminum conductor shall not exceed 20,000 lbf/in 2 or 1 38 MPa when specimens are tested at the speed and using the equipment and procedure indicated in ASTM B 566-04a. The elongation of the same specimens shall not be less than 1 5 percent in 1 0 inches or 250 mm. 1 1 .1 revised July 28, 2008 12 – 19 Reserved for Future Use

494.1 GENERAL – Infrared Analysis is to be used as the method for the identification of nylon or TPE wire and cable compounds. Interpretation of infrared spectral transmittance is to be used to identify the composition of a compound by comparing the compound’s infrared spectra to the spectra of materials having known compositions. 494.2 The analysis is to be performed with a Fourier Transform Infrared (FTIR) Spectrometer and/or a Dispersive Infrared Spectrophotometer. The results are to be recorded as a plot of the percent transmittance of the infrared radiation through the sample versus the number of wavelengths in one centimeter [the reciprocal wavelength (cm -1 ) or ″wavenumber″] of the radiation. Percent transmittance is to be expressed on the ordinate and wavenumber on the abscissa. The infrared spectra obtained by the methods described is to consist of a wavenumber range of at least 4000– 400 reciprocal centimeters. 494.3 SAMPLE PREPARATION – The general polymer-specimen preparation techniques for infrared analysis include solvent casts, potassium bromide (KBr) pellets, solvent-slurry KBr pellets, glass-plate cast films, and reflectance accessories. Solvents typically include chloroform, o-dichlorobenzene, formic acid, and m-cresol. Precautions are to be taken for the safe handling, storage, and disposal of each solvent employed.UL 1581-2008 pdf download.

UL 1581-2008 pdf download