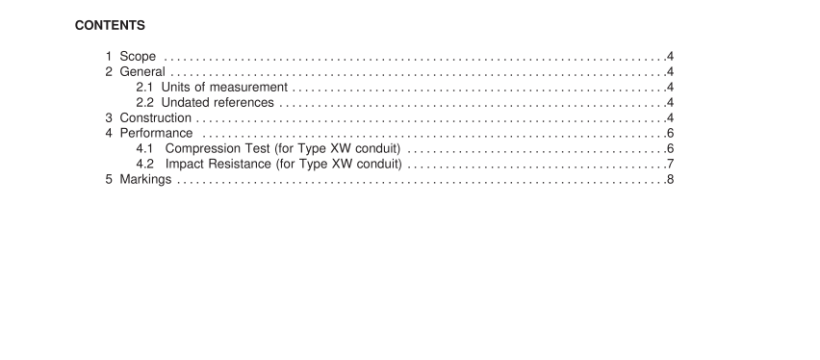

UL 1684A-2007 pdf download.Supplemental Requirements for Extra Heavy Wall Reinforced Thermosetting Resin Conduit (RTRC) and Fittings.

1 Scope 1 .1 These requirements are supplementary to the applicable requirements in the Standard for Reinforced Thermosetting Resin Conduit (RTRC) and Fittings, UL 1 684. Products covered by these requirements are for use in the United States only. References to requirements in UL 1 684 are in italics for easy identification. 1 .2 This standard covers aboveground (AG) extra heavy wall conduit, Type XW (dimensions based on wall thicknesses). Trade sizes (metric designators) are 1 /2 (1 6), 3/4 (21 ), 1 (27), 1 -1 /4 (35), 1 -1 /2 (41 ), 2 (53), 2-1 /2 (63), 3 (78), 3-1 /2 (91 ), 4 (1 03), 4-1 /2 (1 1 6), 5 (1 29), and 6 (1 55). Note: The values in parenthesis are metric size designations of conduit and fittings and do not necessarily reflect metric trade sizes. 1 .3 AG Type XW is suitable for concealed or exposed work where subject to physical damage. 2 General 2.1 Units of measurement 2.1 .1 Values stated without parentheses are the requirement. Values in parentheses are explanatory or approximate information. 2.2 Undated references 2.2.1 Any undated reference to a code or standard appearing in the requirements of this standard shall be interpreted as referring to the latest edition of that code or standard. 3 Construction 3.1 Only materials that are acceptable for the particular use shall be employed. 3.2 Conduit with an integral belled end – The dimensions of conduit with an integral coupling on one end shall be in accordance with the values specified in Table 3.1 . They shall also meet the requirements of Clause 5.8 and Tables 1 and 2 of the Standard for Reinforced Thermosetting Resin Conduit (RTRC) and Fittings, UL 1 684.

4 Performance 4.1 Compression Test (for Type XW conduit) 4.1 .1 The internal diameter of conduit shall not decrease by more than 25 percent during application of an 8900 N (2000 lb) force when tested in accordance with 4.1 .2 – 4.1 .4. The conduit shall show no evidence of cracking or buckling after removal from the compression machine. 4.1 .2 The apparatus for this test shall consist of: a) An inside micrometer or telescopic gauge and a micrometer caliper; b) A compression machine having 2 steel platens at least 1 50 mm (6.0 in) long and 1 0 mm (0.4 in) thick and capable of running at a speed within the range of 1 0 – 1 5 mm/min (0.4 – 0.6 in/min). 4.1 .3 The specimens shall consist of three 1 50 ±3 mm (6.0 ±0.1 25 in) lengths of conduit. 4.1 .4 The inside diameter of the specimen shall be measured and recorded. The specimen shall be placed between the plates of the compression machine such that the measured inside diameter is perpendicular to the platens. The machine shall be set in motion until the force specified in 4.1 .1 has been applied to the specimen. The machine shall be stopped and the inside diameter remeasured. The percent decrease in the internal diameter shall be calculated and recorded.

4.2 Impact Resistance (for Type XW conduit) 4.2.1 When tested in accordance with 4.2.2 and 4.2.3 there shall not be any fracture or break in the laminate surface of seven out of ten 200 mm (8.0 in) specimens of the finished conduit. A fracture or break is considered to have occurred where a broken section of the laminate forms a protrusion within the inside diameter or extends beyond the outside diameter of the conduit. The portions of the conduit within 50 mm (2.0 in) from the cut ends of the specimen shall not be examined. 4.2.2 The specimens are to be cut from finished lengths of each trade size of conduit. Each specimen is to be tested separately while resting on a solid, flat, steel plate that is at least 1 3 mm (1 /2 in) thick and is firmly anchored with its upper surface horizontal. A protective cage is to surround the plates and the specimen to reduce the likelihood of injury. 4.2.3 The impact energy is to be provided by a weight of 34.1 kg (75 lbs) in the form of a 1 50 mm (6.0 in) solid right-circular steel cylinder with a flat impact face having rounded edges, as shown in Figure 4.1 , falling freely through a vertical guide and supplying the impact force specified in Table 4.1 . The flat face of the weight is to strike the center of the specimen. Provision is to be made for keeping the weight from striking the specimen more than once.UL 1684A-2007 pdf download.

UL 1684A-2007 pdf download